3D Print with Supports: A Comprehensive Guide

The world of 3D printing is fascinating and versatile, opening up endless possibilities for design and manufacturing. One essential aspect that plays a pivotal role in creating intricate and complex designs is the use of supports. In this article, we explore the concept of 3D print with supports, understand the types and the considerations for using 3D printer supports effectively. The use of supports has expanded the capabilities of 3D printing, allowing for more complex shapes and structures. This innovation has made 3D printing a more viable option for many industries, from aerospace to healthcare.

Introduction to 3D Print Supports

3D print supports are essential structures built alongside the main object during the printing process to support overhanging parts, bridging gaps, and ensuring that the print doesn’t collapse or warp. These supports are temporary and removed after the print is complete. Understanding when and how to use 3D printer support can make the difference between a successful print and a failed one. With the right application of supports, designs that were once impossible to print become feasible. It’s a skill that takes practice and an understanding of the printing process, but it’s crucial to the successful creation of many 3D objects.

Why Use 3D Printing Supports?

The necessity for 3D print supports arises when a design has overhangs or bridges that exceed a particular angle – usually around 45 degrees. Without support, these overhangs might droop or collapse during printing. The 3D printer supports to ensure that the design maintains its shape, symmetry, and integrity. They are not part of the final product but a means to achieve the desired outcome. The careful use of supports can lead to more precise and accurate prints. On the other hand, improper use can lead to problems in the finished product, emphasizing their importance in the 3D printing process.

Types of 3D Print Supports

Various types of supports are used in 3D printing, and the choice depends on the printer, material, and design. Here’s a brief look at some common types:

Tree Supports: These have branches like a tree and minimize contact with the model, making them easier to remove.

Linear Supports: These are straight lines and are typically used in Stereolithography (SLA) printing.

Grid Supports: Used in Fused Deposition Modeling (FDM), these supports provide a grid-like structure and offer strong support.

Soluble Supports: Made of materials that can dissolve in water, these supports are great for complex geometries as they can be easily removed without damaging the model.

The type of support can drastically affect the final quality of the print, so understanding the suitable support for a specific application is vital. Experimenting with different support types and learning how they affect the final product can lead to better outcomes and more efficient printing processes.

Considerations for Using 3D Printer Supports

When planning a 3D print with supports, several factors must be considered to achieve optimal results:

Design Complexity: Understanding the design and where supports are needed is essential. Software tools can automatically generate support, but manual adjustments may be required for complex designs.

Material Choice: Different materials require different support structures. For example, using soluble supports with compatible materials can make post-processing easier.

Printer Technology: Depending on whether you are using FDM, SLA, or another 3D printing technology, the type and approach to support may vary.

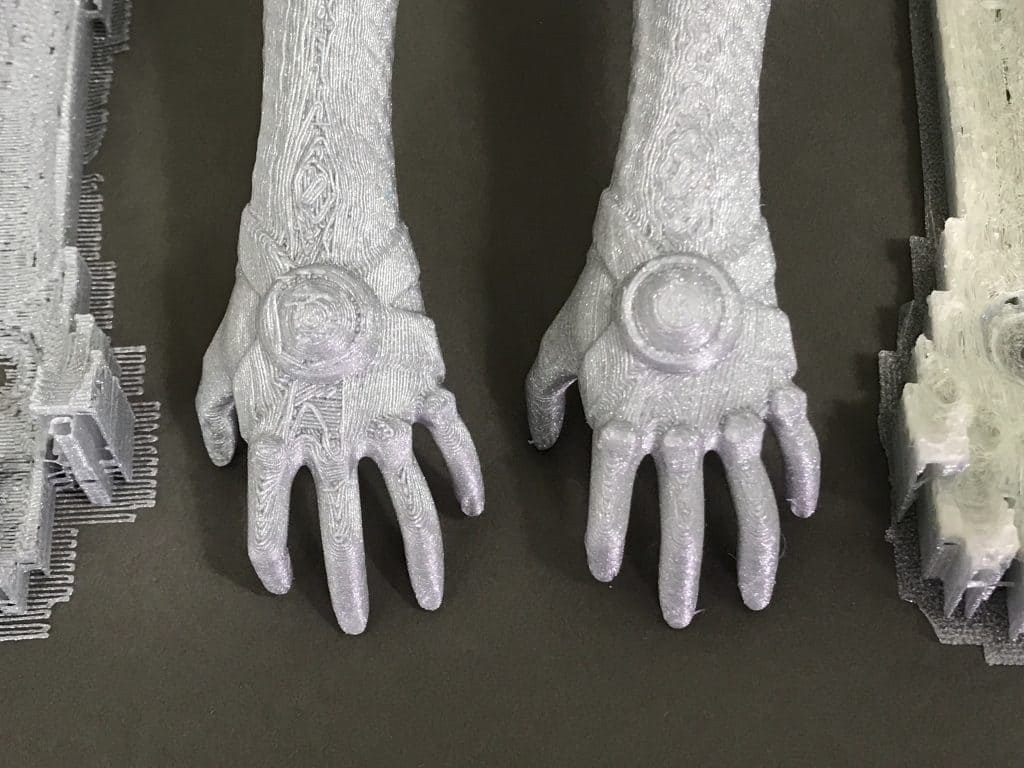

Removal Process: 3D print support removal should be done carefully to avoid damage to the model. It often involves cutting, sanding, or dissolving the supports, depending on the type.

Considering these aspects helps in creating a seamless 3D printing experience, enhancing the final product’s quality and efficiency. It’s essential to balance all these factors, keeping in mind the project’s requirements and constraints.

Challenges of 3D Printing with Supports

3D print supports are indispensable for complex prints, but they come with their challenges:

Material Wastage: Support structures consume additional material, which can increase costs.

Post-Processing Time: Removing and finishing the print after support removal can be time-consuming, requiring care and expertise.

Potential Damage: If not handled correctly, support removal might lead to surface damage or deformations.

Addressing these challenges requires careful planning, execution, and understanding of both the material and the printing technology. By anticipating these challenges and preparing for them, one can mitigate potential issues and achieve successful prints.

Best Practices for 3D Print with Supports

Here are some best practices to ensure the effective utilization of 3D printer support:

Optimize Support Placement: Utilize software to place supports accurately but also manually review and adjust if necessary.

Choose the Right Type: Match the support type with the material and printer technology for optimal results.

Consider Print Orientation: Sometimes, changing the print’s orientation can reduce the need for extensive support.

Test and Experiment: Especially for complex designs, conducting small tests and iterating can save time and material in the long run.

These best practices serve as a roadmap for both beginners and experienced 3D printers. Applying them in your 3D printing projects will likely lead to better quality prints, reduced costs, and a more enjoyable printing experience.

Conclusion

3D printing with supports is a vital aspect of 3D printing that enables the creation of complex and intricate models. It’s a blend of art and science, requiring careful consideration of design, material, technology, and post-processing.

The concept of 3D print supports has expanded the horizons of what’s achievable with 3D printing, making it a crucial skill for hobbyists and professionals alike. By understanding the types of 3D print with supports, why they are necessary, and how to effectively utilize 3D print with supports, one can unlock new potentials in 3D printing. The importance of 3D print supports will continue to grow as technology advances, reflecting the increasing complexity and sophistication of designs. With the right knowledge and practice, one can master this essential aspect of 3D printing, contributing to the broader evolution of this exciting field.