The Complete Guide to 3D Concrete Printing

Amid labor shortages and supply disruptions, 3D concrete printing emerges as a solution for faster, cost-effective construction. By prefabricated structural modules under controlled conditions and assembling them on-site, time and money are saved, and construction progress is no longer hindered by harsh weather conditions.

The Ultimate Guide to 3D Concrete Printing

In this guide, we explore the basics, benefits of 3D concrete printing, providing valuable information for those interested in utilizing this innovative technology for their next construction project.

[Source]

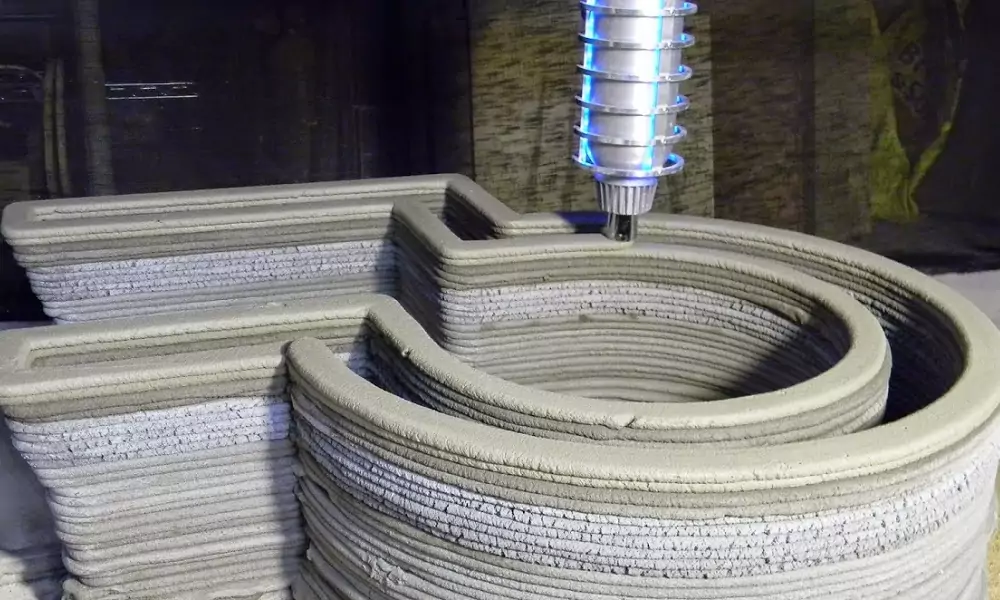

How to Use 3D Concrete Printing

Concrete 3D printing allows for the use of various materials, including mortar, plastic, recycled materials, local resources like moon rock and Mars dust, as well as sand, metal, and clay. Traditional concrete is typically unsuitable for 3D printing due to nozzle clogging and poor adhesion. However, innovative methods, such as adding substances like D.fab, have made it possible to transform traditional concrete into a malleable material suitable for 3D printing. This versatility opens up new possibilities for sustainable construction using local, waste, and recycled materials.

Benefits of 3D Concrete Printing

Builders are realizing the benefits of 3D printing technology for constructing houses, schools, offices, and places of worship. These advantages include:

– Reduced material consumption through optimized and partially hollow wall structures.

– Minimal waste as large-scale concrete molds or formwork are no longer necessary.

– Faster construction times compared to traditional bricklaying or concrete molding methods.

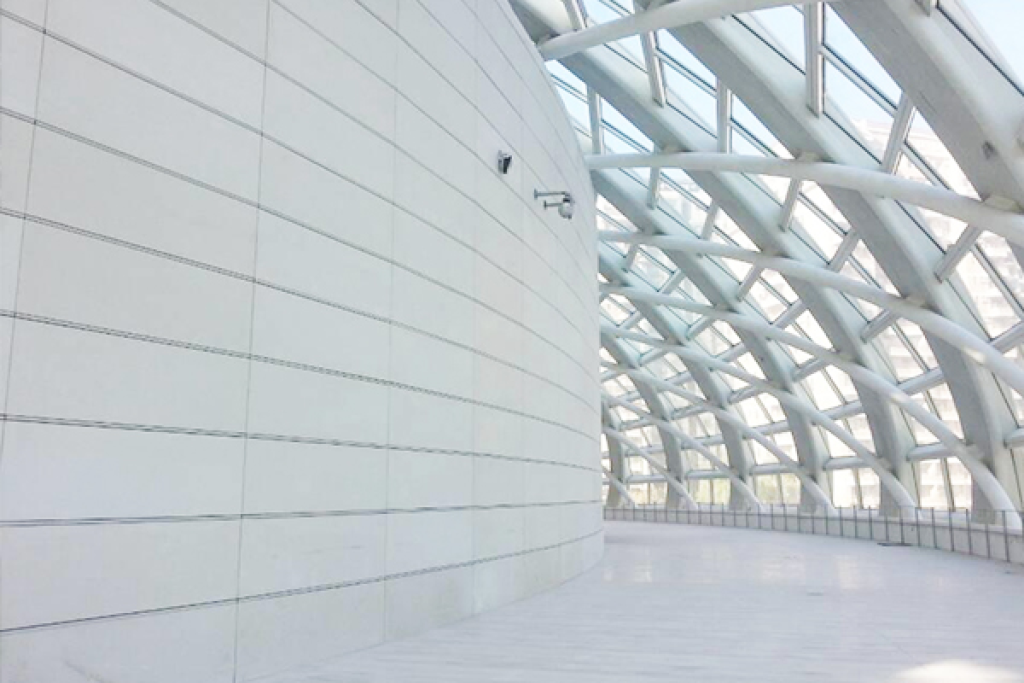

– Greater design freedom to create complex geometries, curves, and hollowness that are difficult with traditional methods.

– Higher productivity with the ability to print continuously, 24/7.

– Lower labor requirements due to the automation provided by 3D printing.

In summary, 3d printed concrete offers efficiency, sustainability, and design flexibility for the construction industry.

Where to Purchase a 3D Concrete Printer

– COBOD: Leading provider of BOD2 3D printers, modular and priced from €180,000 to over €1 million.

– Apis Cor: Offers Frank, a movable robotic arm printer for up to two-story tall prints.

– WASP: Provides 3MT Concrete and Crane Wasp printers, offering convenient shipping container solutions.

– 3D: Supplier of Nexcon gantry printers for cost and time-efficient construction.

– Vertico: Develops concrete printing solutions with flexible robot configurations.

– MudBots: Offers concrete 3D printers for dwellings, statues, bridges, and fountains.

– Twente Additive Manufacturing: Dutch manufacturer of gantry and robotic arm printers, including the high-end Leonardo model.

– CyBe: Provides mobile and fixed robotic arm printers for concrete construction.

– Constructions-3D: French company offering turnkey on-site concrete 3d printer solutions.

Materials Compatible with 3D Concrete Printing

1. CyBe

– CyBe Mortar: Developed specifically for CyBe printers, a non-metallic, low-chloride, and low-sulfate material.

– Sets in three minutes, achieves structural strength in an hour, with high durability and minimal shrinkage.

– Suitable for architectural, structural, industrial, and design applications.

– Can be produced from locally available materials, reducing shipping costs.

– Reduces CO2 emissions by 32% compared to traditional Portland cement.

2. HeidelbergCement

– i.tech 3D: Developed by Italcementi, a subsidiary of HeidelbergCement.

– Versatile material compatible with various 3D printers.

– High pumpability and good extrusion properties, forming strong bonds with previous layers.

– Suitable for printing straight or curved finished parts, weight-bearing elements, and components.

– Formulation can be adjusted for different printing processes and conditions.

3. Icon

– Lavacrete: Proprietary Portland cement-based blend for use with Icon’s Vulcan II printer.

– Compressive strength of 6,000 psi, can withstand harsh weather conditions.

– Eliminates the need for cladding, framing, and sheetrock, reducing costs.

– Provides good thermal insulation for improved comfort.

– Customizable blend with additives using Icon’s Magma delivery system.

4. LafargeHolcim

– Partners with construction companies to provide individually formulated 3D printable concrete mixes.

– Provides printable white cement mixture for architectural and art projects.

– Collaborating with COBOD and GE Energy to develop concrete mixture for printing wind turbine bases.

– Released Tector 3D Build, a dry mortar material range capable of high print speeds.

– Suitable for residential and infrastructure projects, allows for vertical printing.

5. CEMEX

– D.fab: Proprietary admixtures that transform conventional concrete for 3D printing.

– Produces more fluid and malleable concrete for efficient pouring during 3D printing.

– Collaboration with COBOD for Angola’s first 3D printed concrete house.

– Admixtures enable concrete to gain shape instantaneously.

6. WinSun

– Crazy Magic Stone (CMS): Artificial stone material based on modified cement mixture.

– Reinforced with enhanced glass fibers, provides smooth finish resembling natural stone.

– Five to 10 times higher mechanical strength than natural stone.

– Used in over 100 projects for printing walls, floors, and roofs.

– Special Reinforced Concrete (SRC): Fiber-reinforced material for complex architectural elements and decorations.

– Offers high strength and durability, customizable mix for specific project requirements.

Limitations and Challenges of 3D Concrete Printing

1. Legal Obstacles: The legal framework for 3D concrete printing is currently limited, leading to uncertainty regarding rights and responsibilities.

2. Unsuitability for All Environments: Concrete’s reaction to high temperatures and uncontrolled weather conditions poses challenges for consistent printing results.

3. Equipment Size Limitations: 3D concrete printing requires substantial-sized printers, making it expensive and less feasible for larger construction projects.

Overall, further legal development, improved formulas for extreme environments, and advancements in equipment size are needed to overcome these limitations in 3D concrete printing.