The Definitive Guide to Robotic Arm 3D Printer Software

Robotic Arm 3D Printer, also known as Robot Additive Manufacturing (RAM), is a form of robotic arm manufacturing. In this innovative process, an industrial articulated robotic arm is employed to move a printhead, facilitating the additive manufacturing of components.

Unlike traditional gantry-based 3D printing methods, RAM utilizes established techniques such as Fused Deposition Modeling (FDM) or Directed Energy Deposition (DED). However, the distinct feature is that the robotic arm dynamically moves and positions the feed material throughout the printing process. Let’s not waste time, below are the guide to Robotic Arm 3D Printer.

Benefits of Robotic Arm 3D Printing:

1. No Supports Needed: Printed parts do not require additional supports, increasing design freedom and saving on material costs.

2. Overhangs and Reorientation: Some manufacturers have overcome the limitation of overhanging designs by reorienting the building platform, allowing the extrusion layer to act as support.

3. Elimination of Slicing Software: Unlike fixed-axis printers, robotic arm 3D printers use multi-axis toolpaths programmed with specialized 3D printing software, reducing the need for traditional slicing software.

4. Customization Potential: Build-your-own approach enables companies to tailor the robot arm 3d printer to their specific requirements, especially in industrial manufacturing settings.

5. Growing Availability: While there are currently few ready-made systems, the technology is becoming more common, particularly in industrial manufacturing where existing robotic arms can be upgraded with new equipment.

6. Broader Reach: Companies facing barriers in building their own systems can turn to bundled solutions offered by distributors like Evo3D, which includes training, support, and essential components for robotic arm 3D printing.

Cost-Effective and Eco-Friendly Materials

The 3D printer arm uses polymer material in pellet or chip form, along with other materials like metal, clay, and concrete. Using pellets allows for cheaper, sustainable options, including the use of recycled plastic. This method also enables faster printing compared to conventional filament-based 3D printers.

Robotic Arms for Metal and Concrete Printing

Robotic arm 3D printers, also known as 3D printing robot, are versatile, handling materials like metal and concrete. They find applications in construction and architecture, with companies like Vertico and Twente AM offering custom configurations for various projects.

Leading Manufacturers of Robotic 3D Printers

The market for robot-assisted 3D printing is niche, resulting in limited printer manufacturers. Currently, it involves mix-and-match options, where robotic arms and extruder end-of-arm tools may be purchased separately. Many companies offer customizable packages, known as cells, to cater to specific printing requirements. As a result, more companies offer robotic arm 3D printing as a service using their own proprietary printers. However, this trend is expected to change as the benefits of robotic arm additive manufacturing become more apparent.

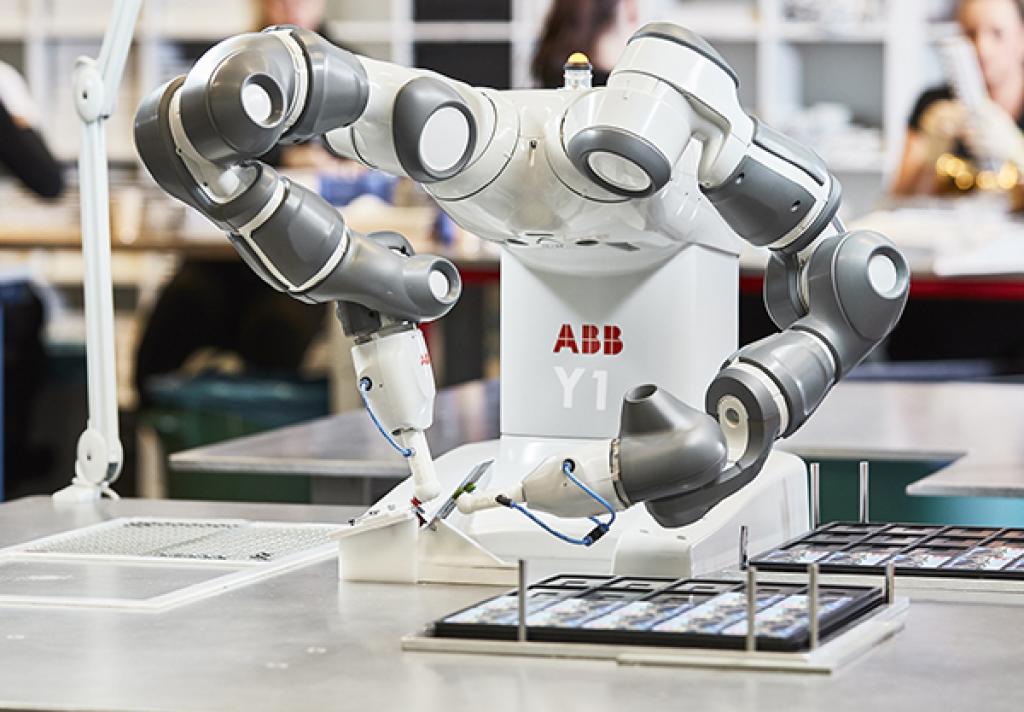

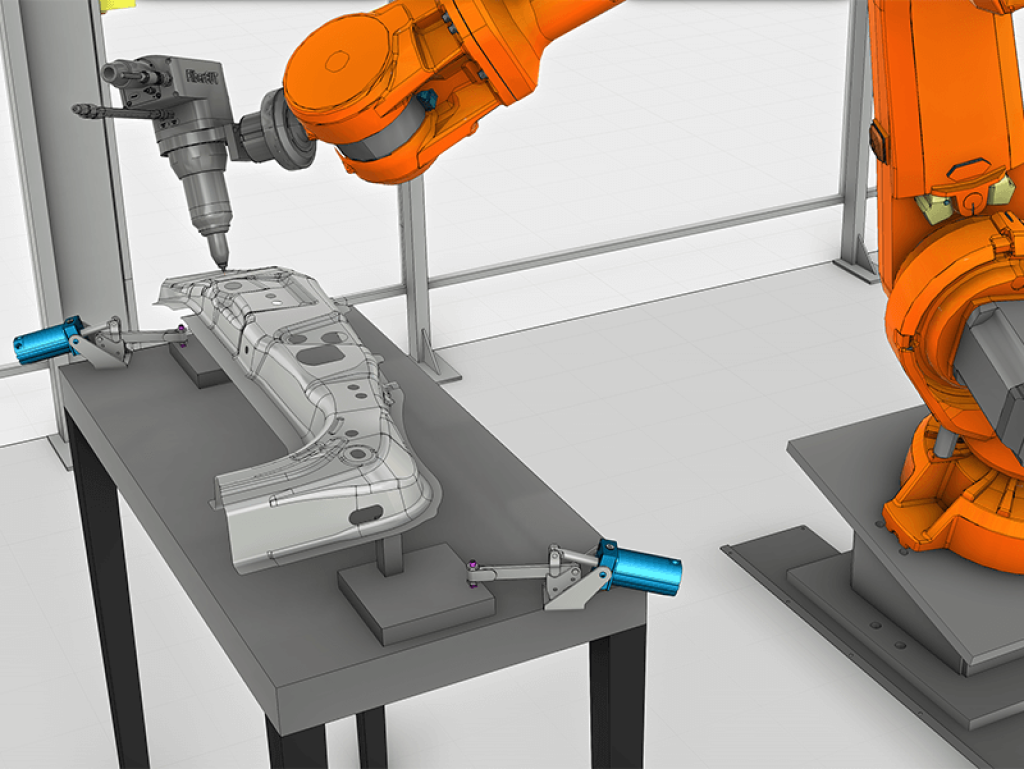

ABB

- ABB Robotics provides a 3D printing arm for various industries, including 3D printing.

- Their flexible and accurate robot arms, like the IRB 7600, are well-suited for additive manufacturing.

- A new version of their RobotStudio software enables 3D printing controls for compatible ABB robot arms.

- At Automate 2022, ABB showcased a 3D printing system with the IRB 4400 robotic arm and a Massive Dimension MDPE10 particle extruder.

- The system is programmed using ABB’s RobotStudio 3D Printing PowerPac, designed for low-volume, high-mix printing.

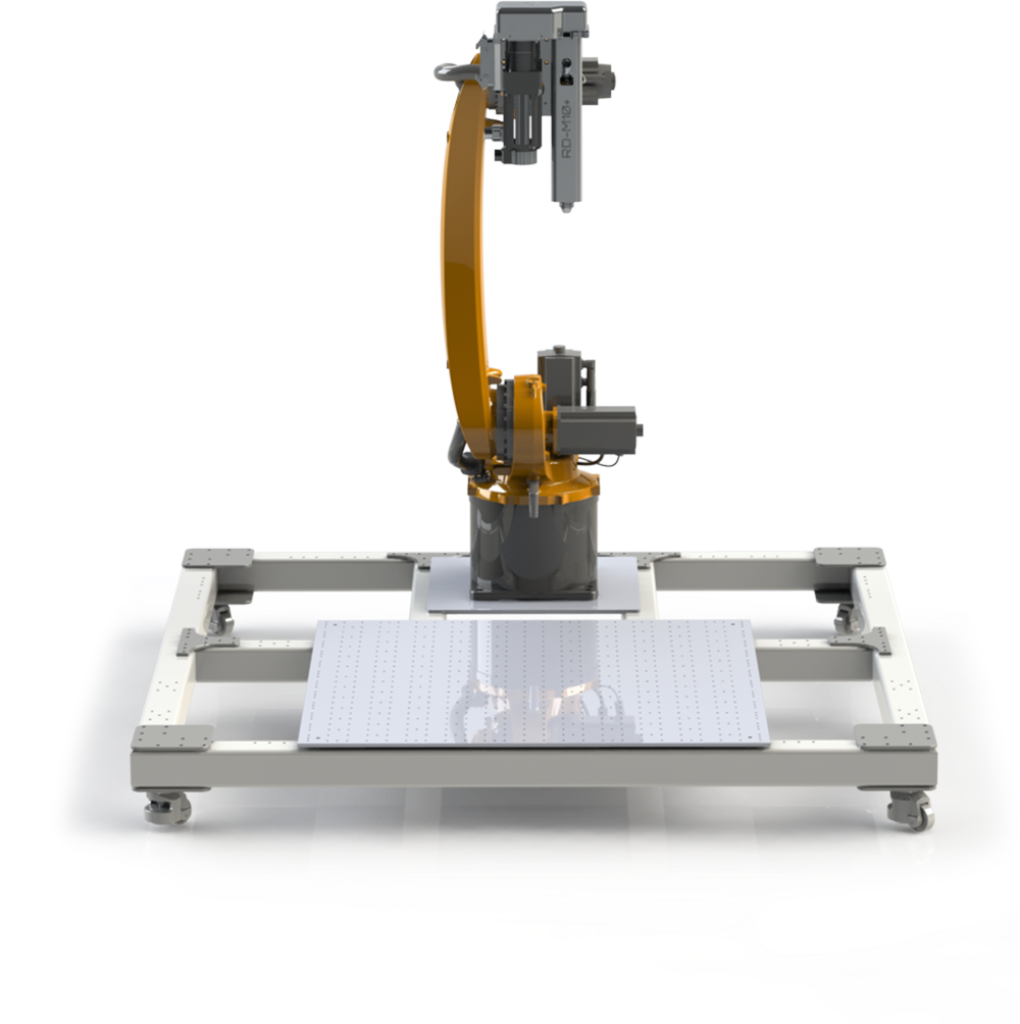

CEAD

- Dutch 3D printing technology supplier CEAD developed the AM Flexbot, a flexible robotic solution for large-scale additive manufacturing.

- The modular system is highly customizable and can be modified for various applications, including CNC milling.

- The CEAD AM Flexbot comes with an extruder capable of handling engineering-grade, high-temperature plastics like PET and ABS-carbon fiber.

- It uses Siemens’ Sinumerik 840D controller, allowing precise manipulation across 31 axes with a printing table of 1.2 x 1.8 meters, eliminating the need for a separate robot controller.

- Optional modules, such as a rotary table and heated working table, can be added to the Flexbot, along with a milling add-on for achieving different surface finishes for mold-making and tooling applications.

- Compatible with any slicing software, CEAD’s Flexbot can easily integrate into diverse manufacturing processes.

- CEAD collaborated with the Technical University of Munich (TUM) to 3D print a mold for a composite flaperon, resulting in faster printing and reduced warping in the final print.

Rev3rd

- Rev3rd specializes in pellet extruders and offers large-format 3D printers and pellet printing services.

- Their extruders feature a quadruple heat zone design, ensuring a constant temperature for the polymer throughout the process.

- The three extruder models, RD-M40, RD-M25, and RD-M10, are robot and CNC machine ready, offering varying output volumes per hour (40kg, 25kg, and 9.5kg).

- Each option can be equipped with an optional venturi feeding system, automatically detecting pellet levels and charging the extruder.

- Pellets can be sourced from bulk supplies or directly from a dryer.

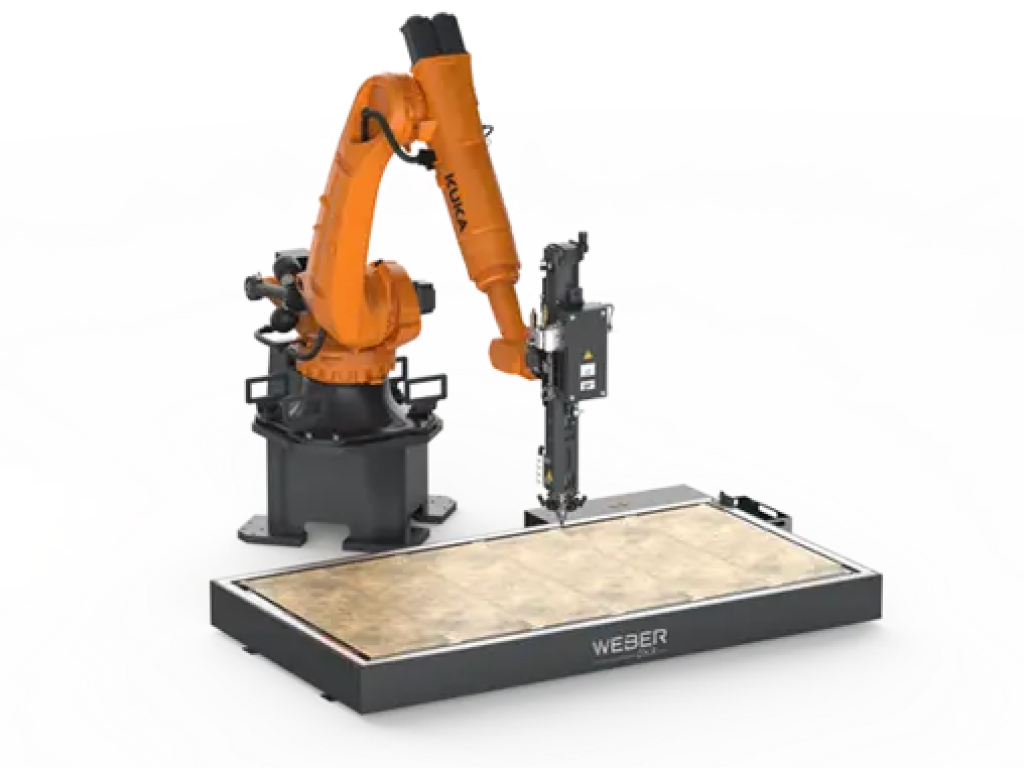

Weber Additive

- Weber Additive offers modular 6-axis industrial robot outfitting with extruders (AE 16, AE 20, AE 30) as the DXR Series package.

- They provide robotic cells, enclosures, and standalone extruders for sale upon request.

- Weber’s extruders can reach 450 °C, featuring tempered feeding zones, water cooling, and interchangeable nozzles.

- The extruders are lightweight, optimized for variable output, and equipped with a powerful servo motor and compact material feeder.

- The right pellet extruder configuration depends on factors like extrusion speed, layer thickness, wall thickness, and material type.

- Weber Additive’s portfolio includes direct extrusion with a gantry system (DX-Series), robotic production cells (DXR-Series), and on-demand parts production.

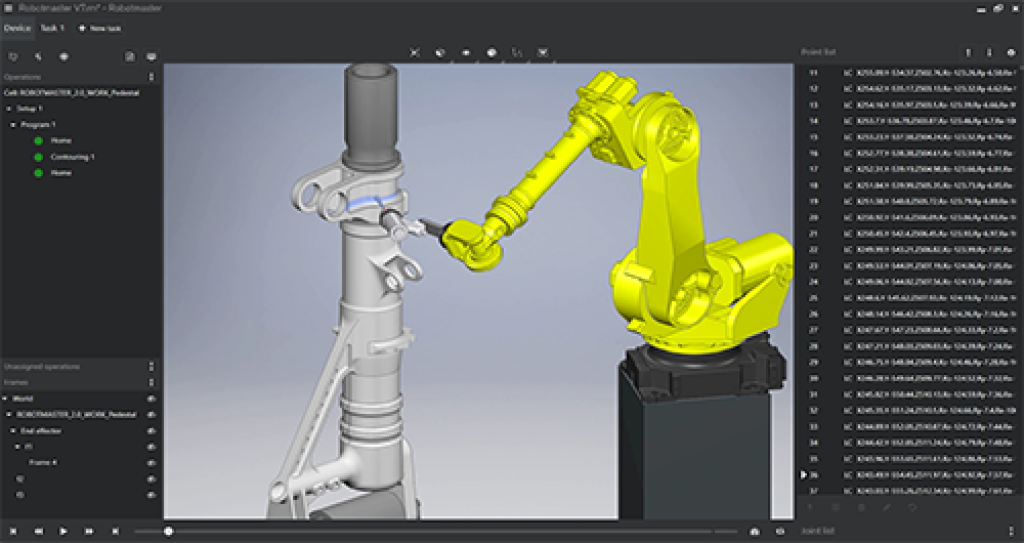

Robotmaster

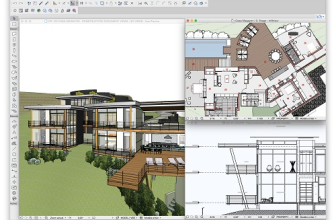

- It offers CAD/CAM software for robot operators to integrate offline programming, simulation, and code generation for additive manufacturing.

- The program provides powerful visualization of issues and errors, ensuring successful prints on the first attempt.

- Automated programming from CAD models can be generated and easily modified for all process-based parameters.

- Robotmaster’s click-and-drag interface simplifies reorienting and optimizing robot arm pathing for better print results.

- It includes single-click contour identification, streamlining the configuration of optimized robot programs without complex simulation skills.

- The software automates challenging tasks in robot programming, leading to faster print times and higher part quality.

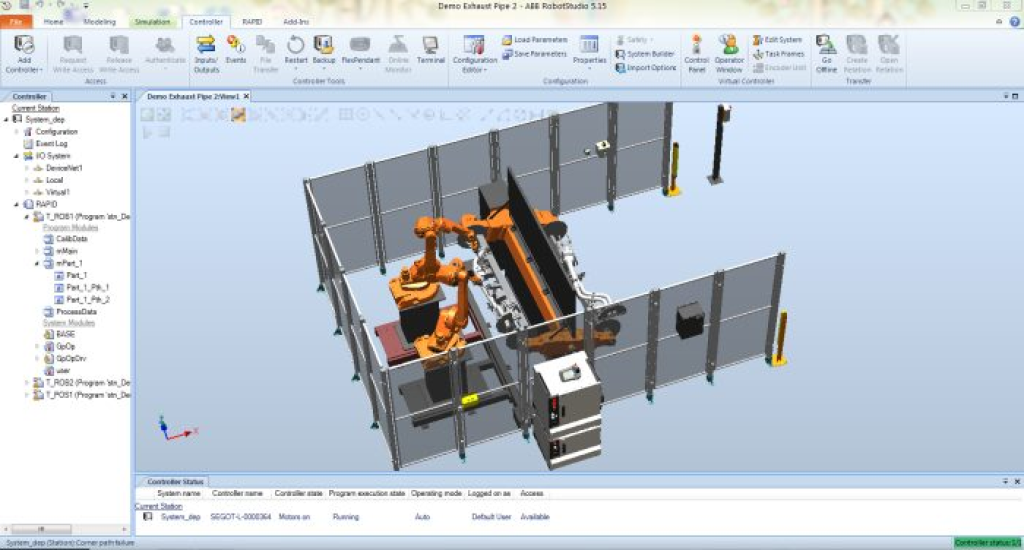

ABB RobotStudio

- It is part of the PowerPac portfolio, offers simulation and programming software for ABB’s robots in additive manufacturing.

- Introduced in 2020, the 3D printing feature eliminates manual programming, enabling faster prototyping.

- The software can translate standard slicer software designs into ABB’s simulation environment and RAPID robot code seamlessly.

- RobotStudio includes G-code filtering for smoother robot movement and supports precise printing with ABB-compatible extruder screws.

Ai Build

- Ai Build’s AiSync software offers automated toolpath generation, process control, and monitoring workflows for extruder-based industrial 3D printers.

- It can control multiple printers on one platform with minimal setup.

- AiSync generates multi-axis toolpaths, not limited to layers like regular slicing software.

- The software includes a geometrical operator library for easy customization and optimization of toolpaths.

- AiSync compensates for issues like warping and layer detachment automatically, with failure detection and predictive analysis functions to optimize printing processes.

- The software finds applications in energy, aerospace, automotive, and construction industries.

Adaxis

- French-Swedish robotics start-up with AdaOne software, enabling any robot to become a flexible 3D printer.

- Robust software for additive manufacturing of metals, plastics, composites, and concrete.

- Comprehensive platform includes simulation, path planning, collision detection, and robot program generation.

- Mission to make advanced manufacturing accessible to all companies, promoting flexibility and sustainability.

Octopuz OLRP

-

- Canadian company with 3.0 update to Offline Robot Programming (OLRP) software.

- Introduces PathPlanner tool suite for enhanced path programming.

- Enables multiple angle settings for precise robot movement reliability in additive manufacturing.

- Capable of analyzing material thickness and quality through advanced simulation features.

- Supports CAM integration and slicer G-code importing.

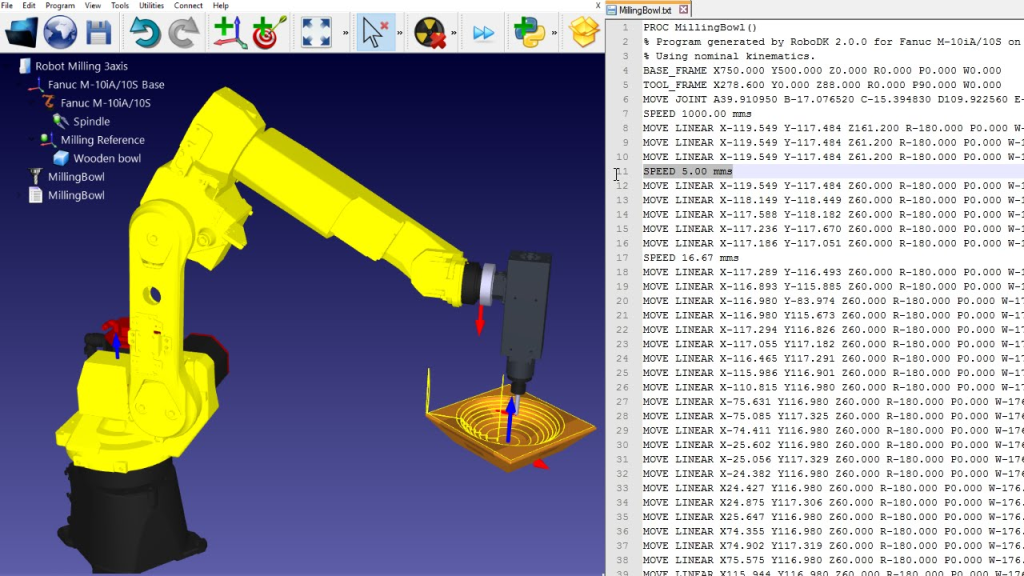

RoboDK

- Canadian software solutions provider compatible with 500+ industrial robots from 50 manufacturers, including ABB and KUKA.

- Users can define their tool by uploading its 3D model through a simple drag-and-drop interface.

- Intuitive CAD/CAM integration creates error-free tool paths, avoiding collisions and axis limits without the need for programming experience.

- Offers over 70 post-processors for diverse robot support.

- Constantly adds new robot compatibility based on user and manufacturer recommendations.

ROBOTIC 3D PRINTING SERVICE PROVIDERS

1. Nagami Design: Spanish company combining 3D printing and robotic manufacturing for large-scale customizable products. Collaborates with renowned designers for groundbreaking creations like the Voxel-Chair v1.0.

2. Branch Technology: Offers C-Fab technology, a 3D printed freeform polymer matrix with a composite material for architectural projects. Provides durable and lightweight structures with high design freedom.

3. Aectual: Dutch design firm with its own XL 3D printing system using ABB robot arm and IRC5 controller. Offers printing in various materials, including concrete, bioplastics, terrazzo, and recycled waste plastics. Collaborates with Tetra Pak and offers custom printing through the Aectual Community.