A Guide to Building a 3D Printer

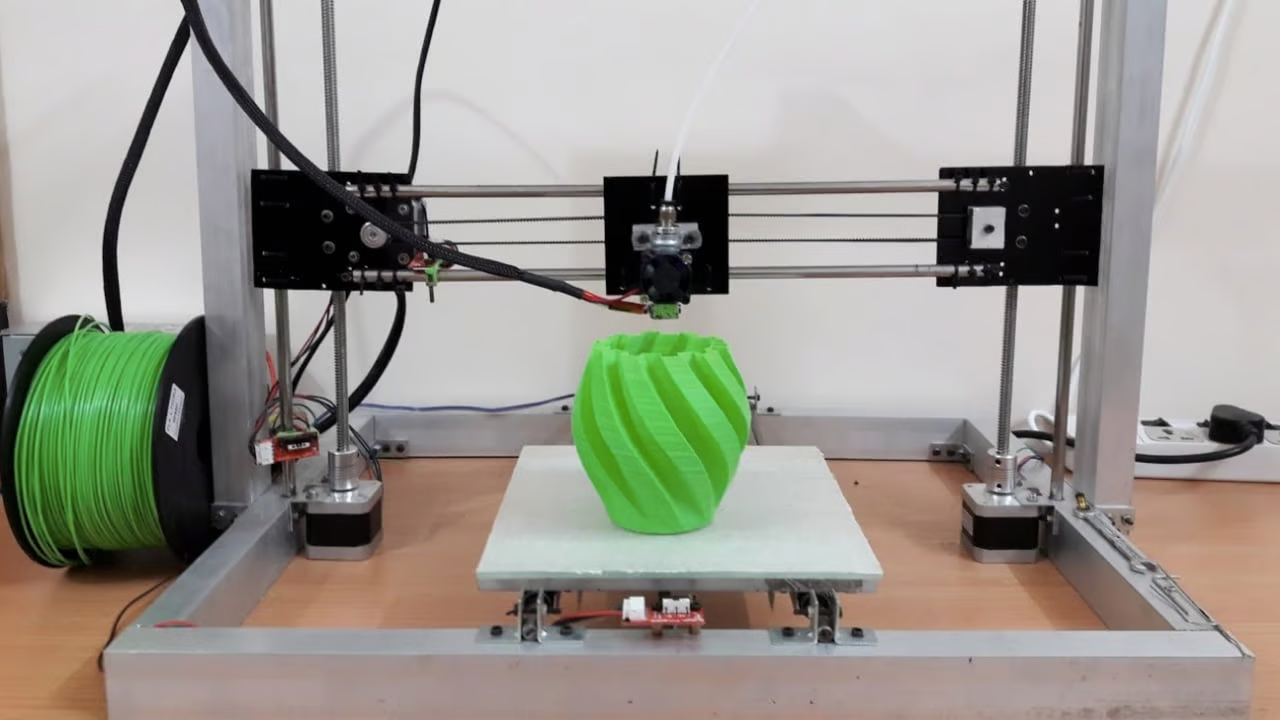

In this article, we explore the evolution of 3D printers from Charles W. Hull’s first model in the 1980s to the present day, where they have become more accessible and affordable. Fused deposition modeling (FDM) has emerged as the dominant desktop type due to its low cost and ease of use. Options range from budget-friendly FDM printers starting at $150 to professional-grade machines exceeding $5,000. For immediate high-quality prototypes, investing in a fully assembled and calibrated 3D printer is recommended.

Alternatively, for 3D printer enthusiasts seeking a challenge and a deeper understanding of the machine, building one from scratch or using a kit is an appealing option. While this approach requires time and patience, it offers a more cost-effective alternative and the opportunity for customization. Building a 3D printer that is good and well- equipped can help to provides many valuable insights into its inner functions and fosters creativity.. In this article, we’ll explore both methods, providing an overview and useful tips to make the process smooth and rewarding. Let’s get started to know how to building a 3D printer

3D Printing Kits

- 3D printer kits are a convenient option as they come with all the necessary parts, tools, and a step-by-step manual.

- They offer similar print quality to fully-assembled machines but at a lower cost.

- Widely recommended 3D printer kits are readily available for purchase online, such as Creality’s Ender series (e.g., Ender 5 Pro), Prusa i3 MK3S, and Tronxy printers (e.g., X5SA).

- Building from a kit eliminates the need to collect, drill, or solder parts and ensures proper voltage matching, as everything is pre-matched by the manufacturer.

- The assembly process is straightforward – follow the instructions provided and put the parts together to build a 3D printer.

Tips:

- Follow the provided instructions and troubleshooting guides carefully before starting build 3D printer

- Some kit manufacturers offer detailed assembly videos, which can be helpful to watch before getting started.

- If you encounter specific problems during assembly, a quick Google search can often provide solutions.

- Be patient with yourself and the process, as it may take some trial and error to get everything right.

- Properly leveling the bed is crucial for successful prints, so ensure you understand how to do it correctly.

- Consider using additional software and firmware to enhance your printer’s performance and capabilities.

- Many free 3D printing software options are available for download, which can significantly improve your printing experience.

Steps to get started:

1. Printer Specifications:

- Determine the size of the printer you want, which will dictate the type of frame needed to diy 3D printer

- Choose the type of printer, determining the movement of the bed and print head

- Decide on the nozzle size, as it directly affects print resolution.

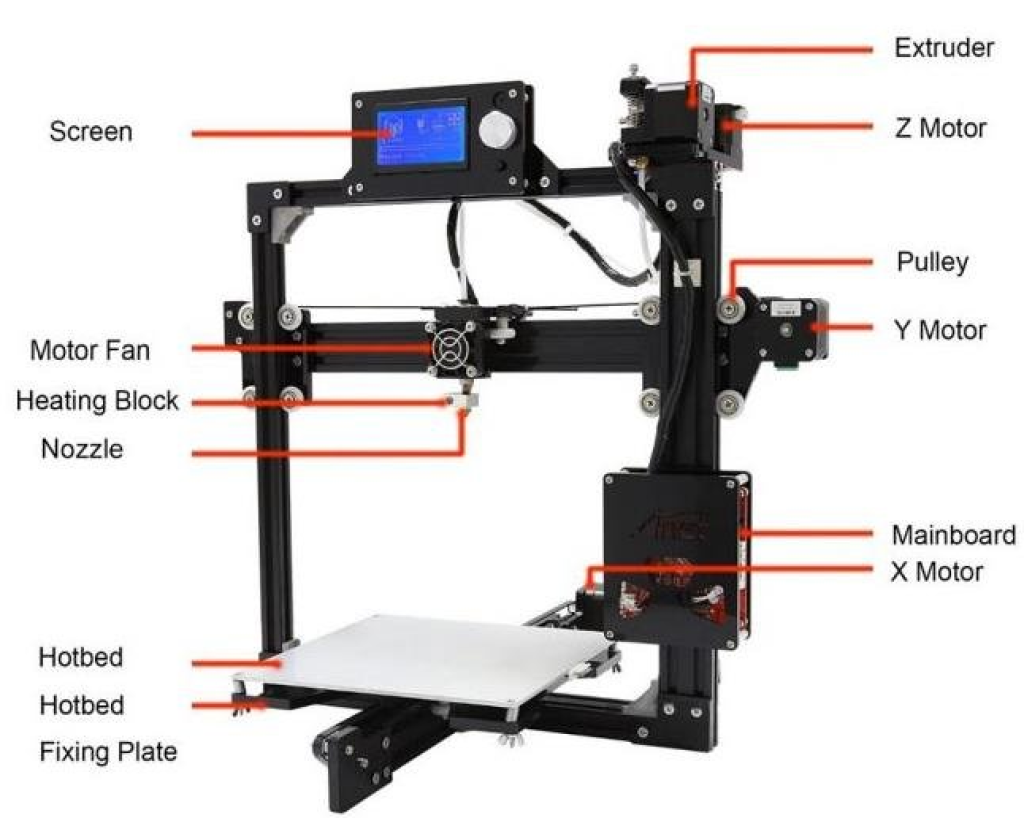

2. Essential 3D Printer Parts:

- Controller: Consider SKR and RAMPS boards, or explore other options for the best control board.

- Stepper motors: You’ll need at least four motors for various axes and extruders.

- Print head: Choose between direct or Bowden extruders and ensure adequate cooling with a fan.

- End stops: These help the print head identify the starting point (0, 0, 0) for movement.

- Print bed: Select a suitable surface for print adhesion, like glass plates or flexible sheets.

- Power supply: Ensure the power supply matches the voltage requirements of the components.

- Printer frame: Consider either purchasing a standard frame or designing and making a custom one.

Build your own 3D printer from scratch offers flexibility and the opportunity to tailor the machine to your specific needs. With the right components and a thorough understanding of their assembly, you can embark on an enriching journey to create your personalized 3D printing device.

Safety Tips

Safety is of utmost importance when working with a 3D printer, and it’s essential to be aware of potential risks. Here are some safety tips to keep in mind:

1. Electric shock: Handle the high voltage power of the 3D printer with caution. Use a power supply unit with a guard for added safety. Double-check and set the correct voltage (110V or 220V) and regularly monitor with a multimeter. Always turn off the power or unplug the machine before connecting parts like motors and sensors.

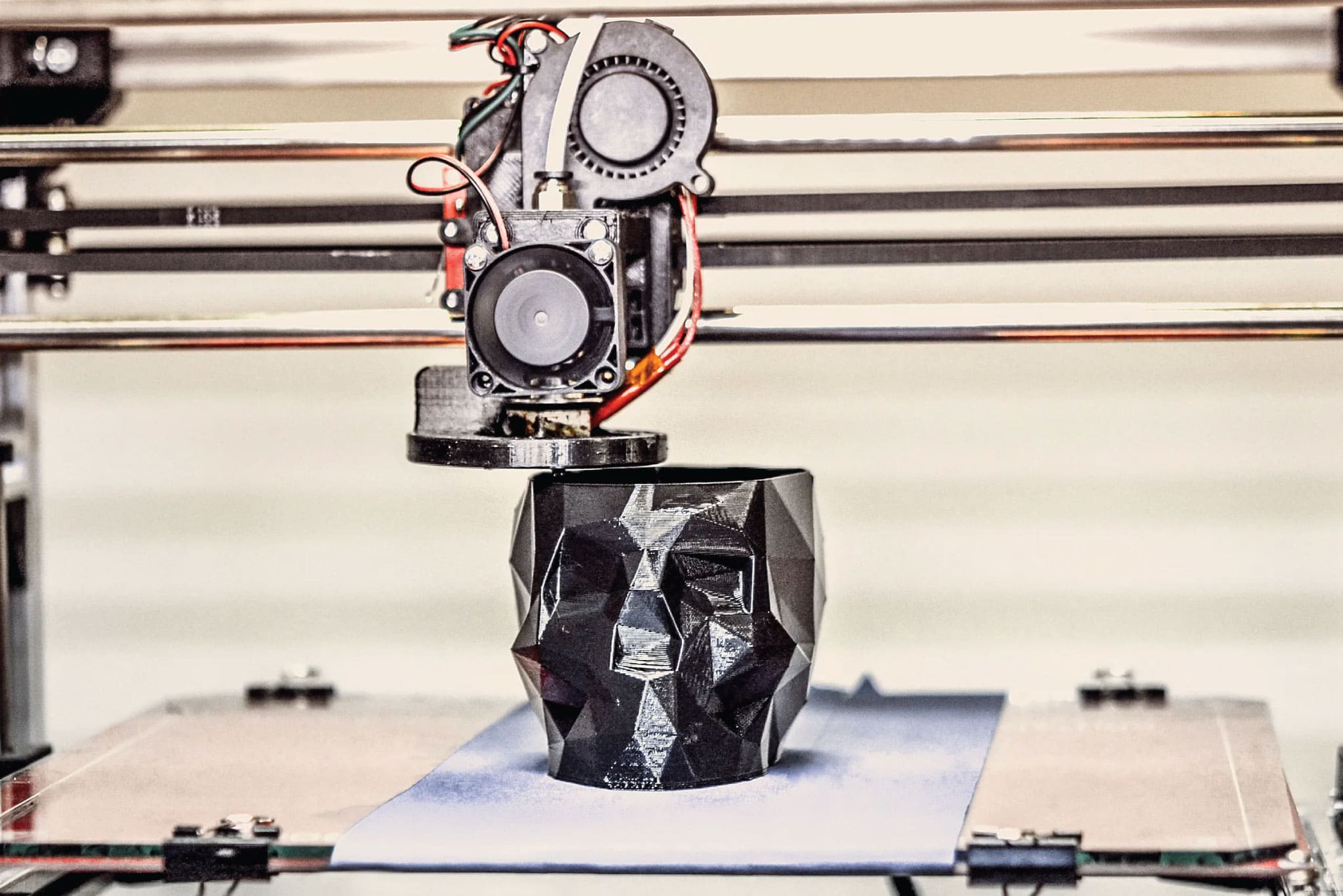

2. Burns: The print head can reach temperatures up to 200°C, depending on the filament used. Be cautious to avoid burns while working with the hot nozzle.

3. Fire safety: Never leave your 3D printer unattended for extended periods, as it poses a fire hazard. Consider using a remote monitoring system like OctoPrint to keep an eye on the printer even when you’re not physically present.

By following these safety guidelines, you can minimize the risks associated with working on a 3D printer and ensure a safe and enjoyable printing experience.

Useful Software & Firmware

Introduction to CAD and Learning Resources

- CAD software is essential for designing 3D models, but beginners may require training and practice to use it effectively.

- Abundant learning resources are available, including tutorial articles and YouTube videos, to help users improve their CAD skills.

- Some CAD companies offer free student versions, like Autodesk, making CAD accessible to students and learners.

CAD Software Options for 3D Printing

- Popular CAD software for 3D printing can be expensive, but there are several free options available.

- Users can explore free software like Cura and PrusaSlicer, both widely used and trusted slicers for 3D printing.

- Simplify3D is a paid option known for its advanced preview capabilities, offering users a comprehensive view of the printing process.

The Role of Firmware in 3D Printing

- Firmware is crucial for 3D printing as it interprets the G-code and controls the hardware components of the printer.

- Marlin is a widely used and popular firmware choice, but users will need to configure it with an Arduino to suit their specific printer setup.

- Repetier is another firmware option, requiring users to edit Arduino files for configuration and offering robust performance with community support.

Join Community

Joining 3D printing communities is a valuable step for those interested in building a 3D printer and exploring the technology further. Here are some excellent communities to consider:

1. RepRap: A popular and well-established 3D printing community offering 3D printing parts for purchase, connections with other makers, and a wealth of helpful information.

2. Instructables: This website hosts numerous articles and tutorials on DIY 3D printers and various other projects, providing valuable learning resources.

3. Hackster: A site featuring free training courses, webinars, and online conferences not limited to building a 3D printer but also covering fascinating electronic projects.

4. 3D Print Forums: An ideal platform for asking questions about 3D printers and receiving expert explanations and insights.

5. Reddit: A massive platform with countless communities dedicated to shared interests, where you can engage, share, and discuss 3D printers with fellow enthusiasts.

By actively participating in these communities, you can expand your knowledge, learn from others, and be part of a supportive network of 3D printing enthusiasts.