Mastering the Art of 3D Printing Prototypes: An Exhaustive Guide

Pitching a brilliant product idea requires more than just words; a detailed sketch or video helps, but nothing compares to a tangible prototype that can be held and examined. Enter 3D printing – the leading method for crafting 3D printing prototypes and models. Its speed, cost-effectiveness, accuracy, and impressive presentation make it a superior choice compared to traditional manual processes like foam carving or clay forming.

A well-executed 3D printing prototypes enhances your product’s appeal, impressing bosses and investors alike. With 3D printing’s ease and affordability, there’s no excuse for outdated methods involving tape and glue.

This comprehensive guide delves into the world of 3D print prototype for product ideas, providing you with all the essential knowledge. You’ll discover how to select the right materials, decide whether to invest in your own 3D printer (and which one), and leverage on-demand 3d printing prototyping services for quick and convenient prototype delivery straight to your doorstep. Accelerate your product development process, test functionality and aesthetics, and unleash the potential of your ideas in record time.

Prototypes for Product Development

In the product development process, before presenting an idea, thorough testing is crucial to ensure its functionality. 3D printing is a valuable tool for creating visually appealing prototypes that are also fully functional for real-world testing. By subjecting prototypes to practical trials, designers can identify and address potential issues in manufacturing or product usage. This iterative testing process helps bring superior products to market.

Now, let’s examine a few examples to illustrate this concept further.

Full Size & Functional

Black Diamond Equipment creates top-notch climbing, skiing, and mountain gear, known for comfort and performance. All their products undergo a rigorous design, testing, and iteration process before hitting the market. They rely on 3D printing for in-house 3D prototype and scaled-down models. However, larger full-scale prototype 3d print were outsourced due to size limitations. The game-changer came with the discovery of the Formlabs Form 3L, a cutting-edge SLA 3D printer capable of handling human-scale prototyping. With this technology, Black Diamond Equipment can now create full-size and functional 3D prototypes in-house, significantly enhancing their design and testing capabilities. This advancement has allowed the company to take their product development to new heights, ensuring top-notch products reach their customers.

Affordable Iterations

Solo entrepreneur Khalid Bou-Rabee took a practical approach to test his home weight-lifting invention. Initially considering costly stainless steel prototypes, he turned to Craftcloud, a 3D printing service marketplace. Using a prototyping 3D printer, he found a strong polymer alternative, enabling him to afford multiple iterations for quick testing and product launch within a year. Functional testing with 3D printing allowed for efficient production of prototypes in the final material, like stainless steel or carbon fiber.

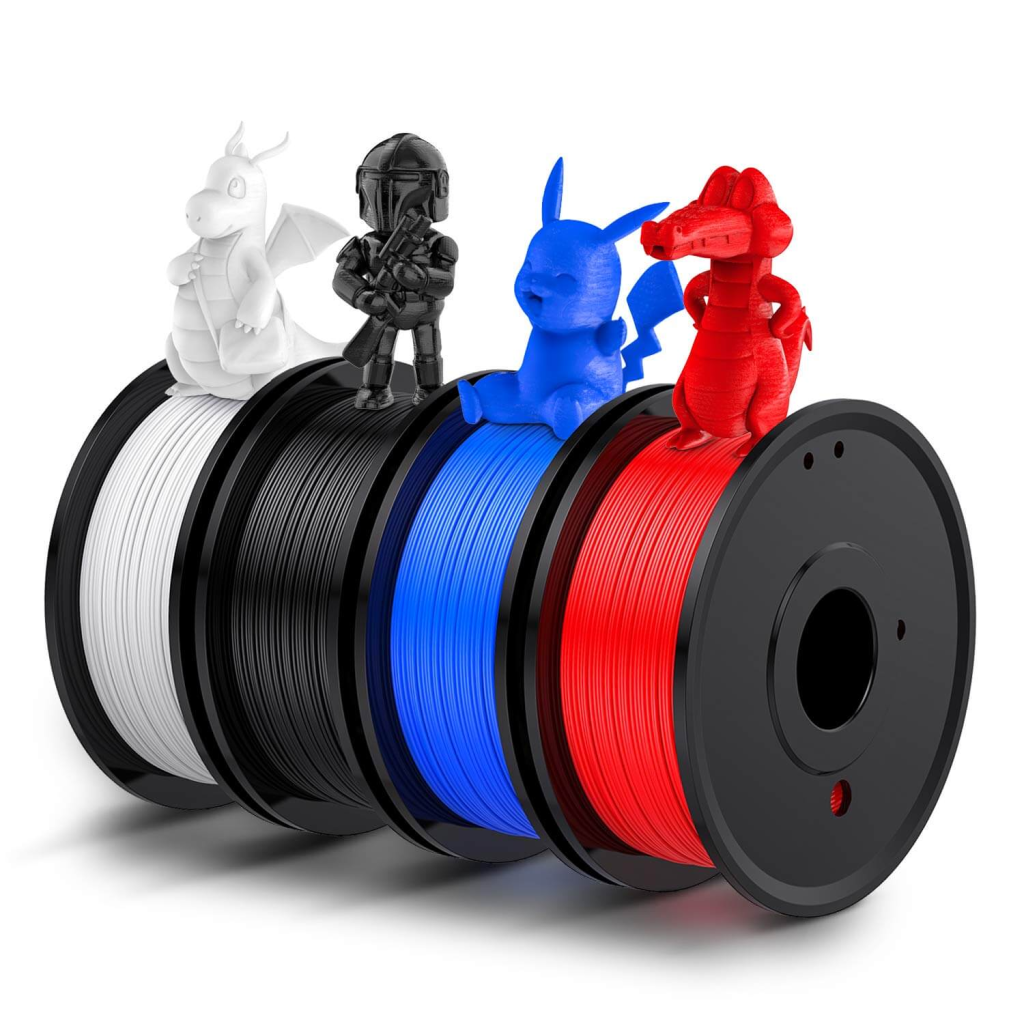

3D Printing Materials for Prototypes

The possibilities for 3D printing materials are virtually limitless, ranging from soft silicone, metals, and tough plastics to conductive copper, sustainable wood, and even edible options like chocolate. With thousands of materials available, it’s possible to 3D print with multiple materials simultaneously.

If you’re uncertain about the best material for your prototype, All3DP offers numerous in-depth guides explaining various materials, their properties, and common applications. Here are a few examples:

– PLA Plastic

– TPU (flexible)

– Stainless Steel

– Carbon Fiber

– Flame Retardant Material

– Nylon

These materials provide a glimpse into the diverse range of options available for bringing your 3D printing projects to life.

Types of 3D Printing for Prototyping

There are various types of 3D printing methods, all widely used for rapid prototyping. Finding the right match for your product involves balancing factors such as cost, speed, material, part complexity, and whether you’ll print it in-house or outsource it to a service.

- Fused Deposition Modeling (FDM) is the most commonly used method for prototypes in plastics due to its versatility and affordability. FDM can handle engineering materials like carbon fiber and even metal filament.

- Stereolithography (SLA) is chosen for parts requiring smooth surfaces and fine details. It uses liquid resin as the base material and excels in creating clear products and intricate components, like jewelry.

- Selective Laser Sintering (SLS) is ideal for functional prototypes intended for testing in demanding conditions. It produces finely detailed parts in materials like carbon-fiber-filled nylon.

- For metal prototypes, metal 3D printing technologies are available, faster and more cost-effective than traditional metal manufacturing methods like casting or machining. They are perfect for producing metal parts with no wasted material and no minimum order quantities when using a service provider.

Final Prototypes for Presentation

After perfecting your product design, it’s time to 3D print the final version. Full-color prototyping is crucial at this stage, achieved through either painting or utilizing a full-color 3D printer. Some 3D printers can handle multiple colors, but full-color options are available from companies like Stratasys, 3D Systems, and Mimaki. These printers offer thousands of color options and precise Pantone matching. While full-color 3D printing can be pricey, using a printing service makes it more accessible.

When you upload your 3D file to a 3D printing service, you’ll get a quote either instantly or a little later by email. However, not all these services are transparent as to how they calculate their prices.

When it comes to material cost, it’s no leap to say that an item printed in PLA will cost significantly less than the same item in sterling silver. Ideally, 3D printing services publish a list that reveals how much a certain amount of the available materials cost. Your price, or rather, the price of material required for your job, is calculated by multiplying the material cost by the volume of the 3D file.

Although 3D printing services are highly automated and use sophisticated software to facilitate every stage of production, there is still some manual labor involved. For instance, after printing, the parts are cleaned, sorted, and packaged. The final cost of a printed item reflects this labor, a part of the “service fee” that is charged per item or order.

Another factor that must be considered to understand how 3D printing services calculate prices is finishing: the sanding, dying, polishing, and other post-processes that help get the most out of your 3D prints. However, since they are often done manually, they will increase the final cost.

Buy a 3D Printer or Outsource to a Service?

In-House Prototyping:

Investing in a 3D printer may seem daunting at first, but it can quickly prove cost-effective compared to outsourcing or traditional production methods. With hundreds of excellent 3D printer brands available, starting your own prototyping journey is accessible. Basic machines can be as affordable as a few hundred dollars, while more advanced models with durable material capabilities start around $3,000.

Many industrial design firms now consider 3D printers standard equipment due to their invaluable role in rapid prototyping. In today’s product development space, having a 3D printer is seen as essential.

Outsourcing Rapid Prototyping:

Outsourcing 3D printing is a simple process—upload your digital file to a service and await your printed prototype. While you don’t need expertise in 3D printing for this option, having some knowledge can help you make better material and technology choices.

Craftcloud, a 3D printing service marketplace affiliated with All3DP, helps you find the best option for your project by comparing instant project quotes from various companies.

When using 3D printing services, the shape of your 3D file can influence pricing as companies maximize machine space by stacking multiple orders together. It’s essential to consider shipping costs, which can vary significantly between service providers. When choosing a service, look for companies that prioritize intellectual property protection.

Conclusion

In conclusion, rapid 3D prototyping is a highly effective manufacturing process that brings significant benefits to engineering workflows. By utilizing 3D printing, you can accelerate your prototyping cycle, reduce costs, and shorten time to market. The ease of design testing and other advantages make it a compelling choice for product development.

When embarking on a 3D printing project, choosing the right manufacturing partner is crucial. RapidDirect stands out as the ideal option for creating high-quality 3D printing prototypes. With cutting-edge technologies, a wide range of materials, and expert guidance, we ensure optimal results for your project. Our quick turnaround times and competitive pricing make us the perfect partner for bringing your ideas to life. Upload your CAD file today, and let’s embark on this exciting journey together!