Laser Cutting on Wood: Precision Crafting Revealed

In the world of modern craftsmanship, laser cutting has emerged as a transformative technique that offers unparalleled precision and versatility. Among the myriad materials that have been shaped by laser technology, wood stands out as a canvas for intricate designs and exquisite detailing. This article delves into the world of laser cutting on wood, exploring its techniques, applications, and the magic it weaves into wooden creations.

With its ability to sculpt wood with unparalleled intricacy, laser cutting has transcended traditional woodworking techniques. This technology harnesses the controlled power of light to etch, engrave, or cut through wood with remarkable precision.

As laser cutting evolves, it blends artistic expression with functional design, enabling creators to bridge the gap between craftsmanship and innovation. Whether it’s crafting delicate filigree patterns or fashioning complex interlocking parts, laser cutting has redefined the art of woodworking by combining tradition with cutting-edge technology.

Unlocking the Potential of Laser Cutting on Wood

Laser cutting on wood involves using a high-powered laser beam to vaporize or melt away material, creating intricate patterns, designs, and shapes with incredible accuracy. This technology has revolutionized woodworking, enabling artisans and designers to achieve levels of precision and intricacy that were once considered unattainable.

By harnessing the focused energy of a laser beam, this process ensures minimal material wastage, resulting in eco-friendly creations. The precision of laser cutting on wood has not only elevated the quality of finished products but also streamlined the production process, reducing time and costs associated with traditional woodworking methods.

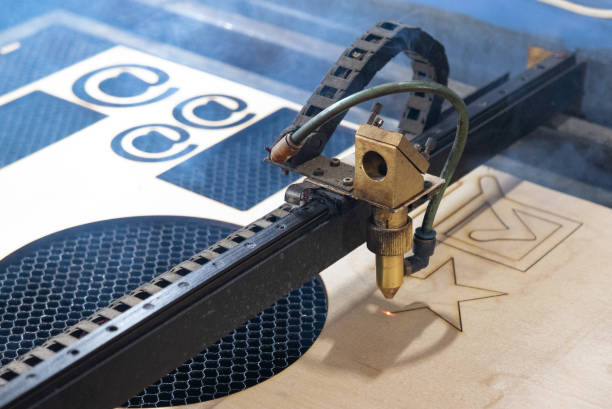

How Laser Cutting on Wood Works: The Process Explained

Laser cutting wood is achieved through a meticulously orchestrated process. A focused laser beam is directed onto the wood’s surface, heating it to the point of vaporization or melting. As the laser beam moves according to the programmed design, the material is precisely removed layer by layer, leaving behind the desired pattern or shape.

This level of control allows for the realization of intricate designs and patterns that were once limited by manual techniques. The layer-by-layer approach ensures that even the most complex shapes can be achieved, transforming raw wood into finely detailed works of art or precisely engineered components.

Types of Wood Ideal for Laser Cutting

Different types of wood react differently to laser cutting due to variations in density, resin content, and grain pattern. Woods like plywood, MDF (medium-density fiberboard), and birch offer consistent and clean results. Hardwoods like oak and maple can also be laser cut, albeit with slightly more variation in outcomes due to their natural grain patterns.

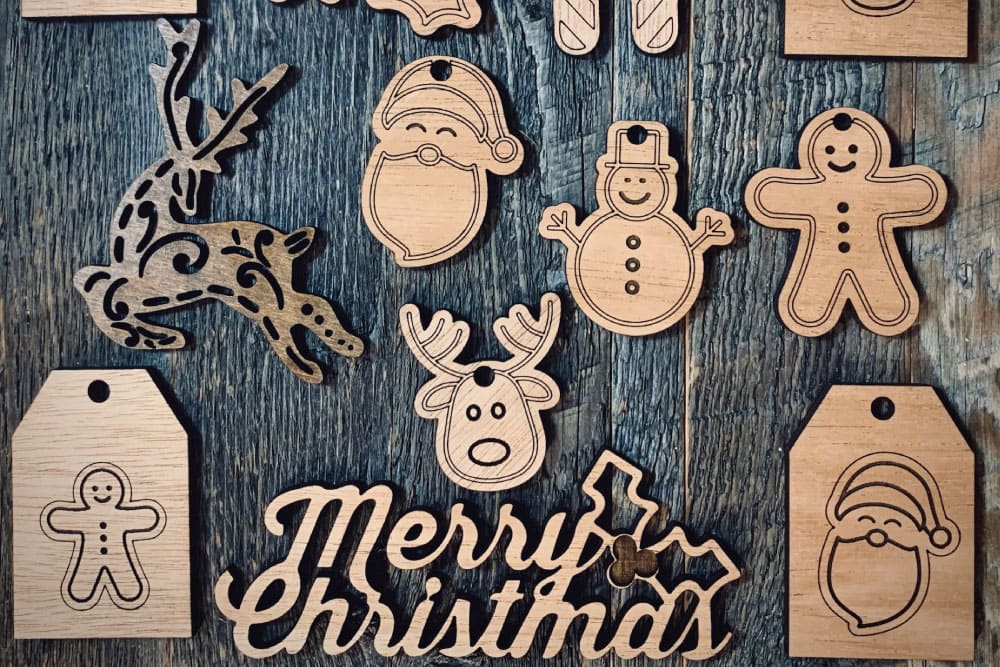

Applications of Laser Cutting Techniques on Wood

The applications of laser cutting on wood span a wide spectrum, from intricate art and delicate jewelry to functional home decor and architectural models. Wooden jewelry pieces adorned with intricately cut patterns showcase the delicate nature of this craft, while laser-cut wooden clocks and lamps bring functionality and aesthetics together seamlessly. Moreover, laser-cut wooden panels find their place in interior design, elevating spaces with their intricate designs and interplay of light and shadow.

Customization and Personalization through Laser Cutting on Wood

One of the most appealing aspects of laser cutter wood is the ability to personalize creations. From engraving names and dates on wooden gifts to crafting unique wooden signs, the laser wood cutter‘s precision transforms ordinary objects into cherished keepsakes.

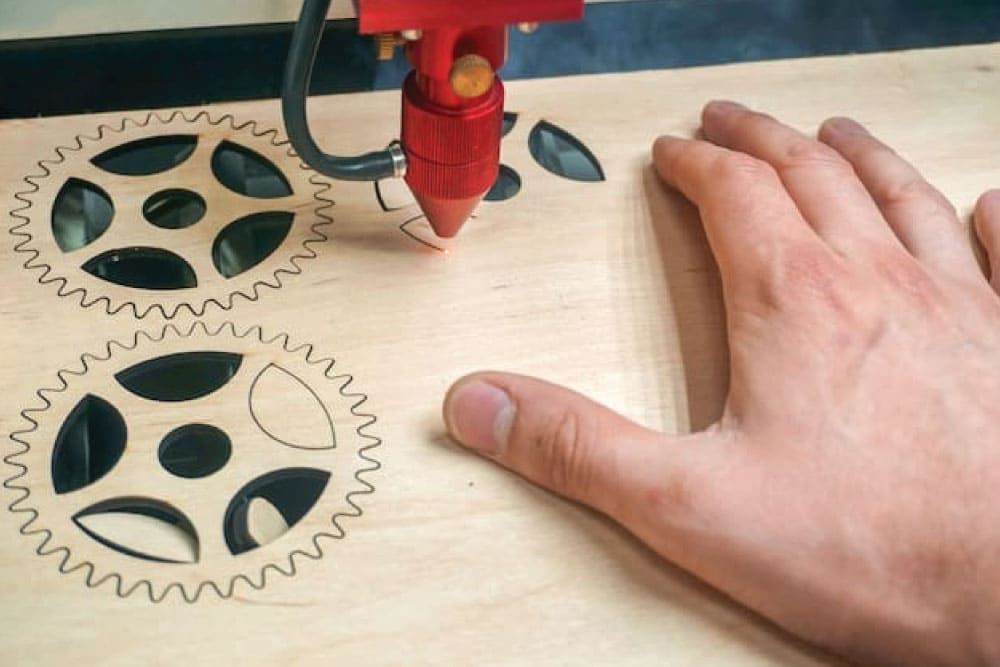

Crafting Intricate Inlays and Joints with Laser Cutting on Wood

Laser cutting on wood is instrumental in crafting intricate inlays and joints that seamlessly fit together. This precision is particularly crucial in furniture making, where complex joinery can elevate a piece from functional to artistic.

Proven Tips for a Successful Laser Cutting Experience on Wood

Material Selection: Choose wood with consistent density and minimal resin content for the best results.

Testing: Always conduct test laser cut wood on a small piece of the same wood to fine-tune settings before embarking on the final project.

Focus and Alignment: Properly calibrate the wood laser cutter‘s focus and alignment to ensure accuracy in the final product.

Ventilation and Safety: Adequate ventilation is essential, as laser cutting can produce smoke and fumes. Also, adhere to safety guidelines to protect both yourself and the machinery.

Conclusion

Laser cutting on wood has redefined the boundaries of craftsmanship, offering a level of precision and detail that was once unattainable. From intricate jewelry to architectural marvels, this technology has transformed wood into a canvas for creativity and innovation. As the art of laser cutting continues to evolve, it’s safe to say that it will leave an indelible mark on the world of woodworking, enabling artists and designers to breathe life into their visions with unparalleled precision and artistry.

The marriage of laser technology and woodworking craftsmanship has birthed a new era of possibilities, where intricate lace-like patterns can coexist with sturdy, functional components. As laser cutting continues to push the boundaries, it becomes an embodiment of the fusion between traditional artistry and modern precision. With each etch and cut, laser technology cements its legacy as a revolutionary force in the realm of woodworking.