Troubleshooting 3D Printing Common Problems and Solutions

3D printing has revolutionized various industries, from manufacturing to healthcare and even hobbyists. However, like any technology, 3D printing is not without its challenges. As exciting as it is to create intricate designs and prototypes, 3D printing common problems is not uncommon. In this article, we will explore some of the most prevalent issues that arise during 3D printing and provide practical solutions to help you overcome them.

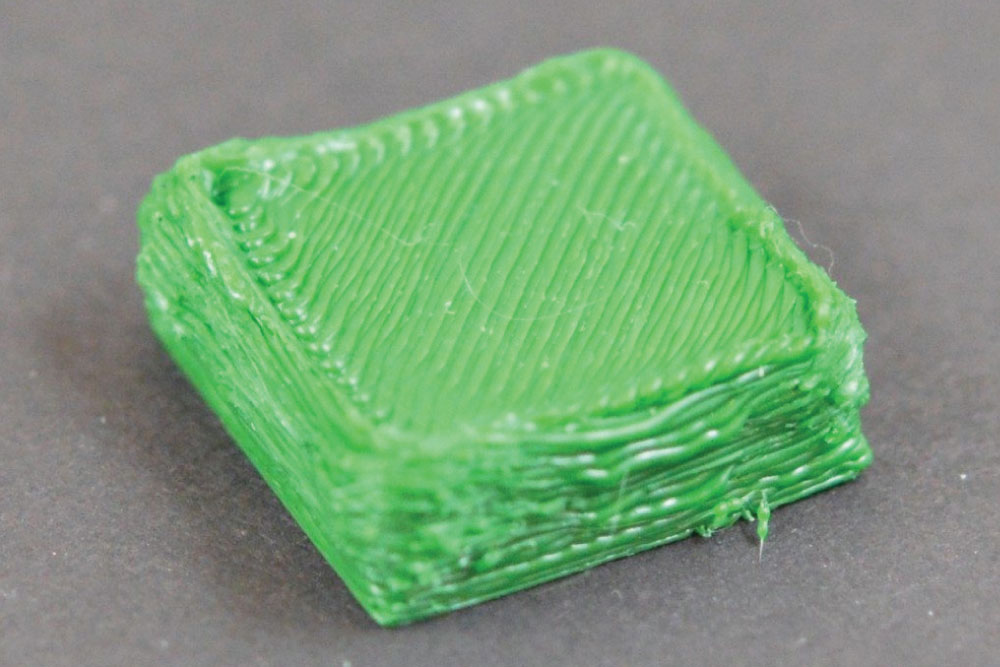

Dealing with Layer Adhesion Issues

One of the most common problems in 3D printing is poor layer adhesion. This occurs when the printed layers do not fuse properly, resulting in a weak and easily breakable final product. Layer adhesion problems can be caused by 3d print issues such as improper printer calibration, incorrect print settings, or using low-quality filament. Layer adhesion problems not only compromise the strength of the 3D printed object but also lead to visible gaps and inconsistencies in the final product. To address this issue, users should carefully inspect their printer’s specifications and settings, ensuring that the nozzle temperature, print speed, and layer height are optimized for the chosen filament material. Additionally, using high-quality and reliable filament brands can significantly improve layer adhesion and produce more durable and robust 3D prints.

Solution

Ensure that your 3D printer is correctly calibrated and that the print bed is level. Use appropriate print settings, including the right temperature for the filament material. Investing in high-quality filament can significantly improve layer adhesion and overall print quality.

Solving Warping and Curling

Warping and curling are one from the 3d printing failures during the printing process, particularly when using materials like ABS. These common 3d printer problems occur due to uneven cooling of the printed layers, causing them to contract and deform. To prevent warping and curling, it is essential to consider using a heated bed or adding a brim or raft to your 3D prints, which can help improve adhesion to the print surface and minimize the impact of temperature fluctuations.

Solution

To prevent warping and curling, it is crucial to maintain a consistent printing environment. Consider using an enclosed 3D printer or implementing a heated bed to ensure even cooling and reduce the chances of warping.

Addressing Nozzle Clogging

Nozzle clogging is another common problem in 3D printing, where the nozzle becomes blocked with hardened filament or debris, leading to irregular extrusion and incomplete prints. Nozzle clogging can be frustrating and disrupt the printing process, but it is often preventable with regular maintenance and proper filament handling. To avoid nozzle clogging, users should store their filament in a dry and dust-free environment, use high-quality filaments, and perform periodic nozzle cleaning using specialized cleaning tools or by performing a cold pull (also known as “atomic” pull) to remove any debris or leftover filament from the nozzle.

Solution

Regularly clean the nozzle to prevent clogging. This can be done by heating the nozzle and using a needle or fine wire to carefully clear any obstructions. Additionally, using high-quality filaments with minimal impurities can reduce the risk of clogging.

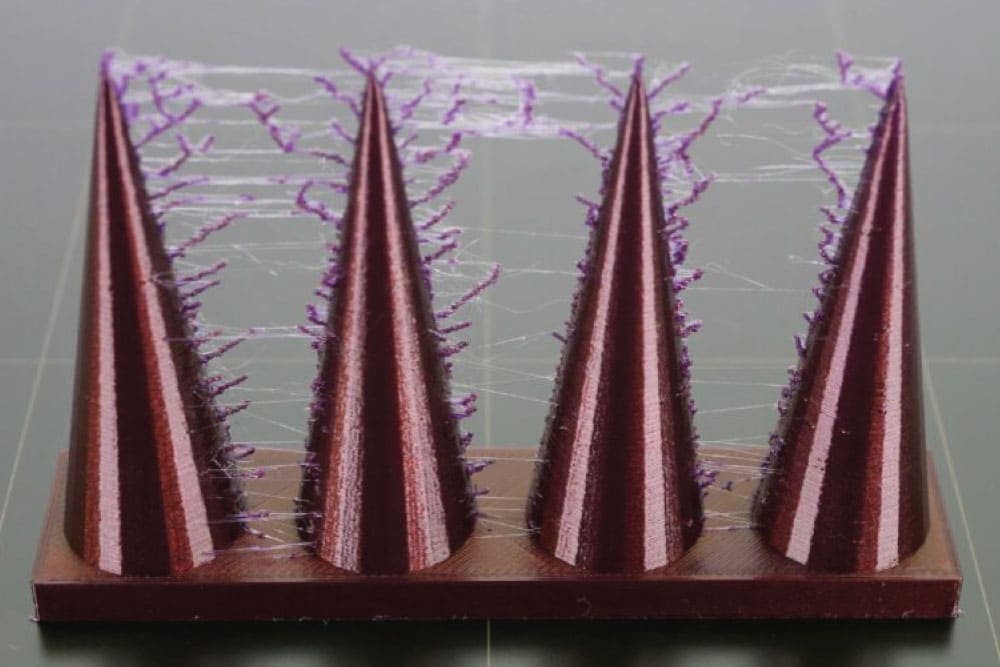

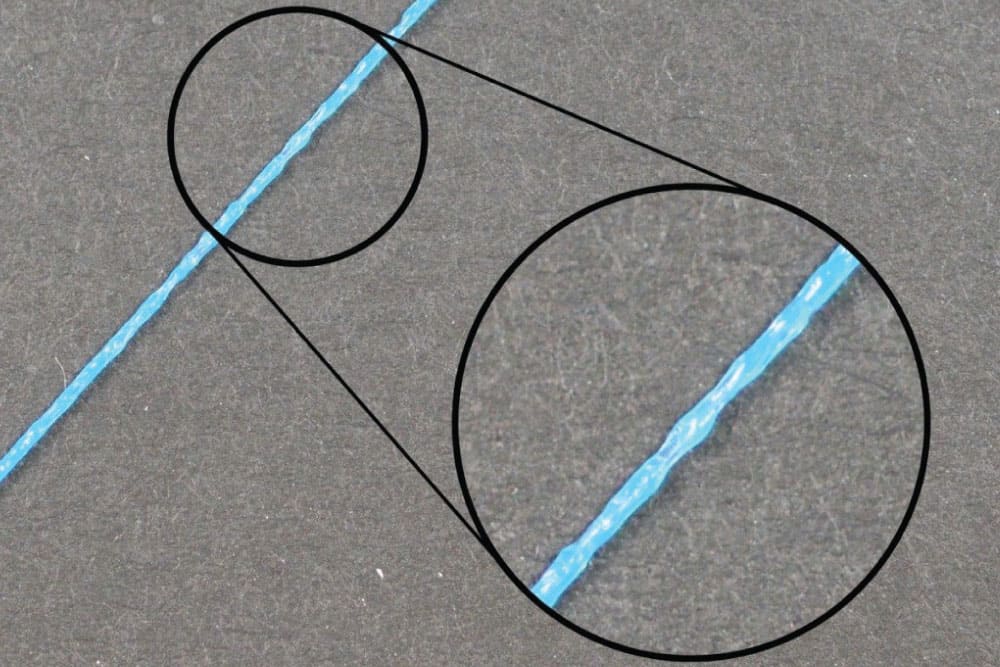

Preventing Stringing and Oozing

Stringing and oozing occur when the printer leaves unwanted strings or blobs of filament between different parts of the print. This issue is often caused by excessive retraction settings or incorrect temperature settings.To reduce stringing and oozing, users can experiment with adjusting the retraction settings in their printer’s software, which controls how much filament is pulled back during travel moves, or try lowering the print temperature slightly to minimize the likelihood of excess filament being deposited between printed parts.

Solution

Adjust the retraction settings in your printer’s software to minimize the amount of filament pulled back during travel moves. Experiment with different temperature settings to find the optimal temperature for your filament to reduce stringing and oozing.

Fixing Inconsistent Extrusion

Inconsistent extrusion can lead to uneven and flawed prints, causing parts of the model to be weaker or distorted.

Solution

Ensure that the filament diameter settings in your 3D printer are accurate. Regularly check the extruder gears and clean them from any debris that may hinder smooth extrusion. Consistently monitor the printer’s extrusion during printing to identify and correct any inconsistencies.

Managing Layer Shifts

Layer shifts occur when the printer’s print head unexpectedly moves along the X, Y, or Z-axis during printing, causing misalignment and distorted prints. Layer shifts can be particularly frustrating as they often ruin an otherwise promising print, but by ensuring proper calibration of the printer’s belts, rods, and stepper motors, users can significantly reduce the occurrence of this issue and achieve more precise and accurate prints.

Solution

Check and tighten all belts, pulleys, and screws in your 3D printer to prevent any unexpected movements. Make sure that the printer is placed on a stable and level surface to minimize the chances of layer shifts.

Handling Elephant Foot

Elephant foot refers to the issue where the bottom layer of a print is slightly wider than the upper layers, resulting in poor dimensional accuracy and fitting problems. Elephant foot is a common problem in 3D printing, especially when printing with materials like ABS, and it can be caused by excessive nozzle pressure on the initial layer or inadequate bed leveling.

Solution

Adjust the initial layer settings in your 3D printer’s software to reduce the pressure on the first layer, preventing it from spreading too much. This adjustment can help minimize the elephant foot effect and improve the overall print quality.

Mastering 3D Printing Challenges

While 3D printing opens up a world of possibilities, it comes with its share of challenges. By understanding and 3d printing troubleshooting common 3D printing problems, you can enhance your printing experience and produce high-quality prints. Regular maintenance, proper calibration, and using quality filament are essential to minimizing 3d printing issues and achieving successful 3D prints. With these solutions at hand, you can confidently explore the endless potential of 3D printing for various applications.