Dealing with Clogged Nozzle 3D Printer : A Guide

3D printing technology has revolutionized various industries, enabling enthusiasts and professionals to turn their digital designs into tangible objects. However, one common issue that 3D printer users often encounter is a clogged nozzle. A clogged nozzle 3d printer can disrupt the printing process and lead to poor print quality. In this article, we will explore the causes of clogged nozzles in 3D printers and provide effective solutions on how to unclog them to ensure smooth and successful 3D printing. The impact of a clogged nozzle goes beyond just affecting print quality; it can also lead to wasted time, materials, and frustration. By understanding the root causes of clogging and implementing preventative measures, users can optimize their 3D printing experience and achieve consistent, high-quality prints.

Understanding a Clogged Nozzle in Your 3D Printer

A clogged nozzle 3D printer refers to the blockage of the small opening through which the melted filament is extruded during the printing process. The filament, usually made of materials like PLA or ABS, can accumulate residue, dust, or impurities over time, leading to a restricted or entirely blocked nozzle. When a nozzle clogged scenario happens, it disrupts the smooth flow of filament, resulting in inconsistent extrusion and layer adhesion issues. This can lead to misshapen or incomplete prints, causing frustration and wastage of both time and materials.

Common Causes of 3D Printer Nozzle Clogging

Poor-Quality Filament

Using low-quality or impure filament can increase the likelihood of clogs. These filaments might contain foreign particles or irregularities that can hinder smooth extrusion.

Incorrect Temperature Settings

Printing at the wrong temperature can cause improper melting and flow of the filament, leading to blockages.

Excessive Retraction

Over-retracting the filament during the printing process can cause the filament to pull back into the nozzle, potentially causing clogs.

Dust and Debris

Dust and debris in the 3D printer’s environment can find their way into the filament and eventually accumulate in the nozzle, causing clogs.

Partially Melted Filament

If the printer is paused or stopped mid-print, the filament in the nozzle may cool and solidify partially, leading to clogs when printing is resumed.

How to Unclog a Nozzle in Your 3D Printer

These are several methods how to unclog 3d printer nozzle.

Cold Pull Method

The cold pull method, also known as the atomic pull or cold end method, is a straightforward technique to unclog a 3D printer nozzle. The cold pull method is an effective technique used to unclog 3D printer nozzles by dislodging stubborn debris or impurities. By heating the nozzle to the printing temperature, loading a small piece of filament, cooling down the nozzle rapidly, and then gently pulling the filament out, the clogged debris is pulled along, clearing the nozzle effectively. This simple yet powerful method is often used by 3D printing enthusiasts and professionals to quickly get their printers back on track and resume high-quality printing.

Heating the Clogged Nozzle

Start by heating the nozzle to the printing temperature of the filament that caused the clog.

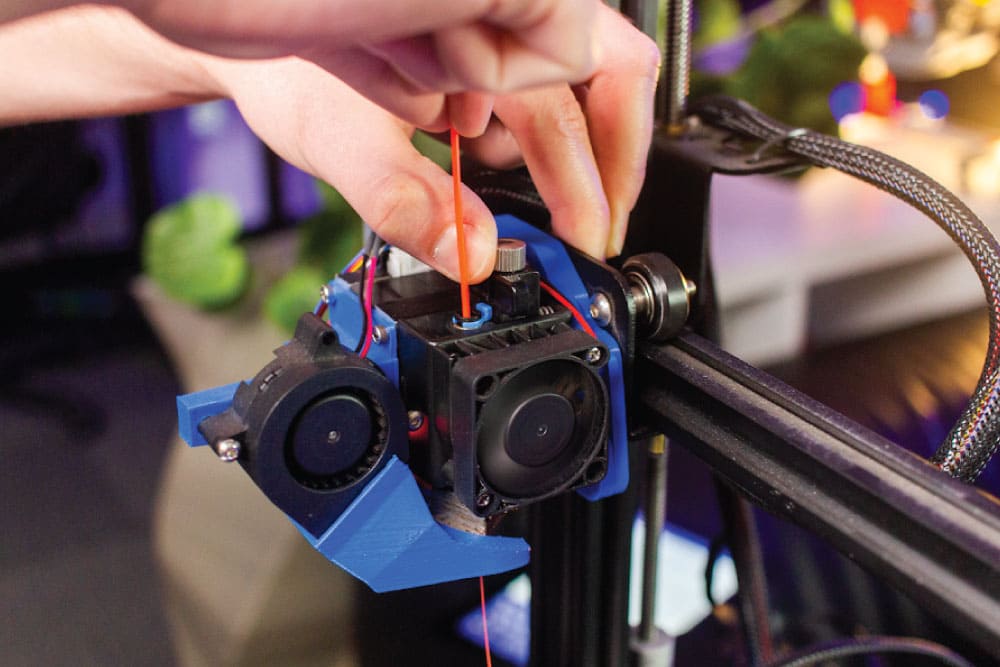

Filament Loading and Unloading

Once the nozzle is at the correct temperature, manually load a small piece of filament into the extruder. Heating the nozzle to the correct printing temperature is crucial, as it softens the clogged filament, making it easier to remove during the cold pull process.

Cooling Down the Nozzle

Immediately after loading the filament, turn off the heat to cool down the nozzle rapidly. Rapidly cooling down the nozzle after loading the filament helps to solidify the filament inside the nozzle. This solidification, combined with the pulling force during the cold pull, effectively dislodges any trapped debris or impurities, clearing the nozzle for smooth 3D printing.

Performing the Cold Pull

Once the nozzle has cooled sufficiently, gently pull the filament out of the nozzle. The cold filament will drag the clogged debris out, effectively clearing the nozzle.

Nozzle Cleaning Kit

Using a nozzle cleaning kit is another effective way to remove stubborn clogs from 3D printer nozzles.

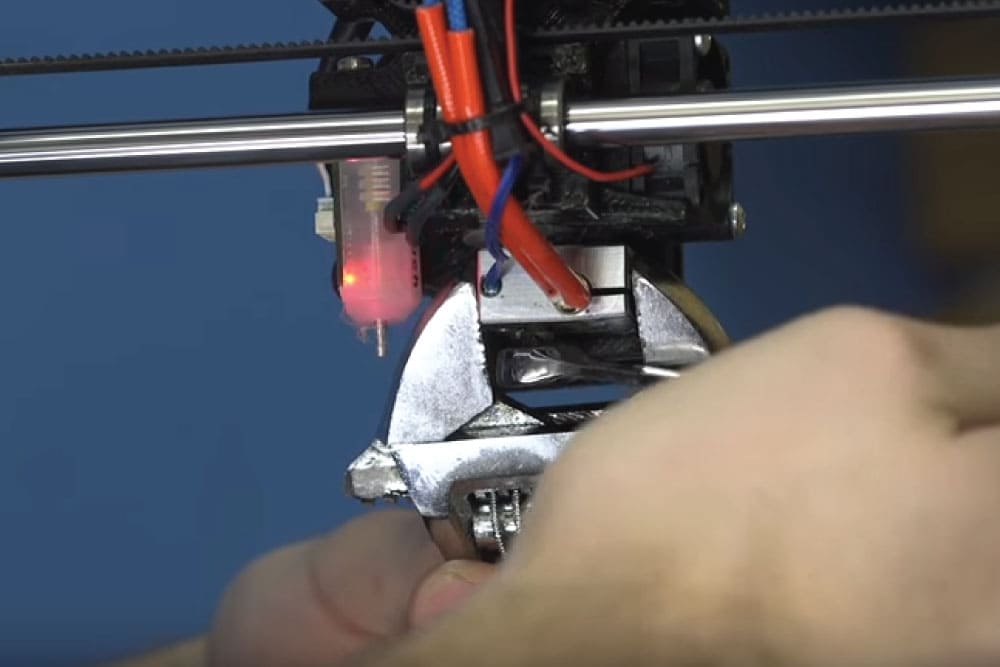

Dismantle the nozzle

Disassemble the 3D printer nozzle, following the manufacturer’s instructions.

Use the cleaning tools

The cleaning kit typically includes small, needle-like tools designed to remove debris from the nozzle’s opening. Gently insert the appropriate tool into the nozzle and clean out any obstructions.

Reassemble the nozzle

Once the nozzle is clean, reassemble it carefully, ensuring that all components are properly aligned.

Filament Change

Sometimes, a clogged nozzle can be a result of poor-quality or contaminated filament. Switching to a different, high-quality filament can prevent future clogs.

Replace the filament spool

Remove the current filament spool and replace it with a new one from a reputable manufacturer.

Check the extruder assembly

Before loading the new filament, inspect the extruder assembly for any residual debris that could lead to another clog.

Preventative Measures for Avoiding Nozzle Clogs in Your 3D Printer

Preventing clogs in the first place can save time and frustration. Here are some essential preventative measures. We should perform routine maintenance on your 3D printer, including cleaning the nozzle, checking for dust or debris, and ensuring proper temperature settings. Furthermore, it is essential for printer users to always invest in high-quality filament from trusted suppliers to minimize the risk of clogs due to impurities. In addition, accurate temperature calibration for your specific filament type is crucial to prevent under or over extrusion, which can lead to clogs. Finally, we also always adjust retraction settings in your 3D printer software to avoid excessive filament retraction and minimize the risk of nozzle clogs.

Conclusion

Clogged nozzles are a common challenge faced by 3D printer users, but with the right knowledge and tools, they can be effectively managed. Understanding the causes of nozzle clogging and employing the appropriate unclogging techniques can ensure smoother and more successful 3D printing experiences. By implementing preventative measures and practicing regular maintenance, you can reduce the occurrence of clogged nozzles, allowing you to unleash the full potential of your 3D printer for creative and precise printing projects.