Desktop Injection Molding Machines: Revolutionizing Small-Scale Manufacturing

Advantages of Desktop Injection Molding Machines

Accessibility of Desktop Injection Molding Machines

Desktop injection molding machines have made the technology accessible to small businesses, hobbyists, and educational institutions. With reduced costs and space requirements, they have democratized plastic molding.

Flexibility in Desktop Injection Molding Machines

The flexibility offered by a benchtop injection molding machine allows for experimentation and innovation on a smaller scale. Short runs and prototypes can be produced without significant investment.

Environmentally Friendly Desktop Injection Molding Machines

Smaller machines mean less energy consumption, aligning with a more sustainable approach to manufacturing.

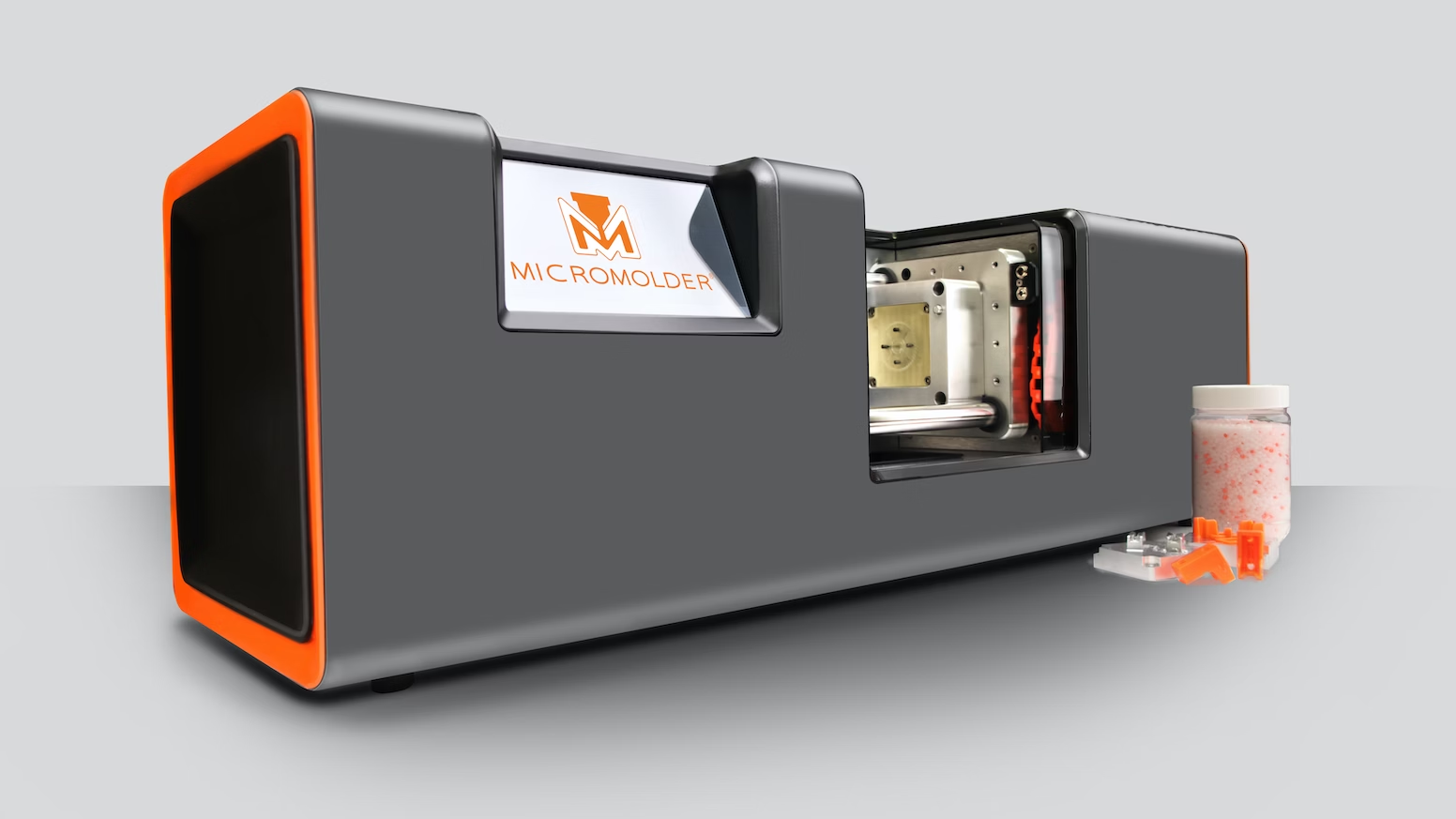

Popular Desktop Injection Molding Machines

Several brands and models have emerged to meet the growing demand for desktop injection molding machines. Here are a few notable examples:

Digital Fabrication Systems (DFS): Ergonomic Desktop Injection Molding Machines

Proto-ject: Offers machines ideal for small businesses and hobbyists.

Galomb Inc.: A popular choice for educational institutions.

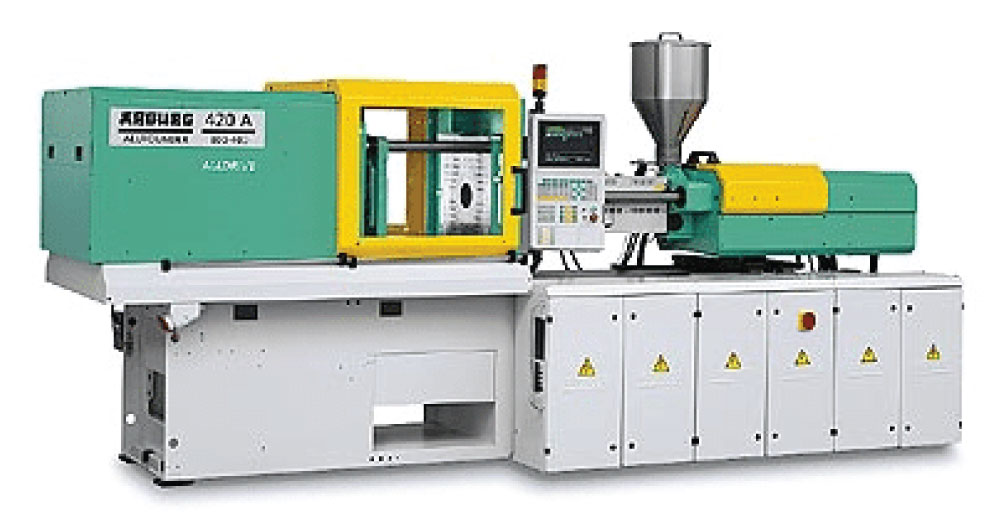

Comparing Desktop Injection Molding Machines with Traditional Machines

While desktop injection molding machines offer many advantages, it’s essential to understand how they compare to traditional full-sized machines.

Scale: Traditional machines can handle large-scale production, while desktop versions are designed for smaller runs and prototypes.

Materials: Desktop machines may have limitations in terms of the types of plastics they can process.

Precision: Industrial-grade machines typically offer higher precision and control.

Applications of Desktop Injection Molding Machines

A desktop or table top injection molding machine has various applications:

Prototyping: Ideal for testing designs before mass production.

Education: Used in schools and universities to teach manufacturing principles.

Small-Scale Manufacturing: Suitable for small businesses producing limited quantities.

Considerations When Choosing a Desktop Injection Molding Machine

When selecting a desktop injection molding machine, some factors need to be considered:

Material Compatibility: Ensure that the machine can handle the specific plastics you plan to use.

Scale of Production: Select a machine that fits your production volume needs.

Budget: Machines vary in price, so choose one that fits your budget.

The Future of Desktop Injection Molding Machines

With advances in technology and growing interest in small-scale manufacturing, the future of desktop injection molding appears bright. Innovations in materials, design, and software integration will likely continue to push the capabilities of these machines.

Integration with 3D Printing: Combining 3D printing with injection molding for hybrid manufacturing.

Increased Automation: Incorporating more automated features for streamlined production.

Customization: More options for customization to suit specific needs.

Conclusion

The rise of desktop, benchtop, and table top injection molding machines marks a significant shift in the plastic molding industry. By offering an affordable and space-efficient solution, they have opened up injection molding to a wider audience. Whether it’s for prototyping, education, or small-scale manufacturing, the advantages of these machines are evident.

The continued growth and innovation in this field will likely see desktop injection molding machines becoming an integral part of modern manufacturing landscapes. Their accessibility, flexibility, and environmental friendliness make them not only a practical choice but also an innovative step towards a more sustainable future in plastic molding. Whether referred to as a desktop injection molding machine, benchtop injection molding machine, or table top injection molding machine, these devices are proving to be invaluable assets in various sectors of the industry.

As technology continues to evolve, we can expect to see even greater enhancements in the capabilities of these compact machines, potentially broadening their applications and further reducing their costs. The wave of innovation in desktop injection molding signifies a promising direction in manufacturing, where quality and efficiency are achievable without sacrificing affordability and accessibility, thus nurturing a new generation of makers and producers.