3D Printing Bridging: How to Create Perfect Bridges

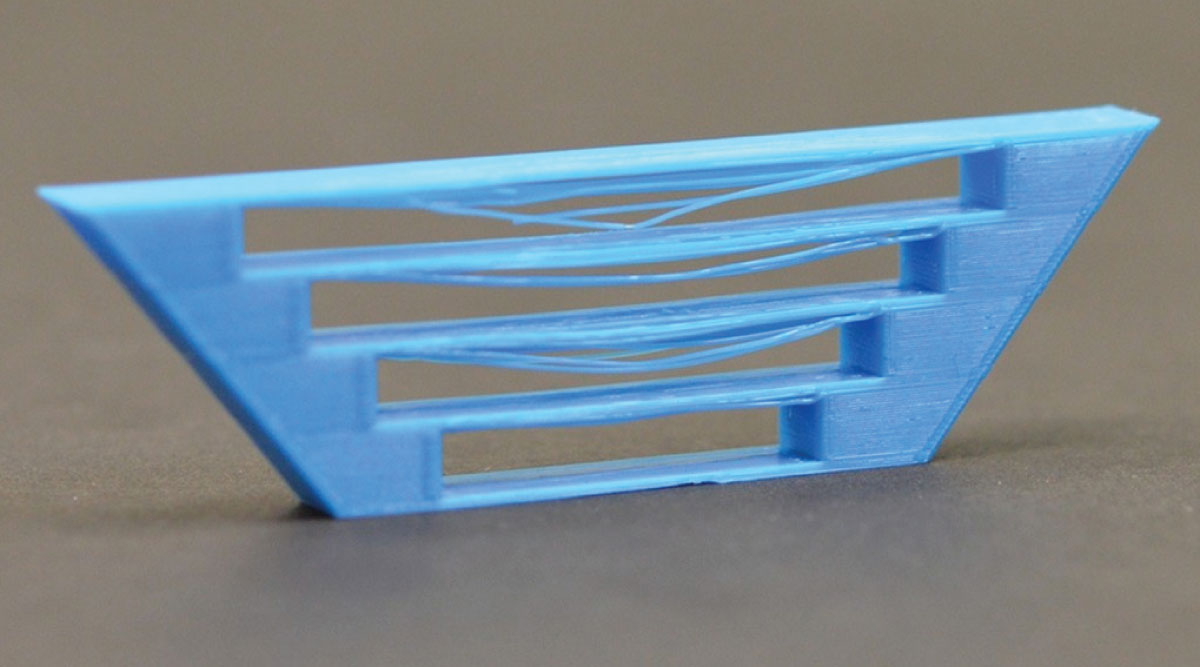

In 3D printing bridging, the printer constructs a horizontal or angled flat section between two elevated points without any supporting material underneath. Bridging 3D printing is often considered an advanced technique and requires a careful understanding of the capabilities of the printer and the material being used. Mastery of this technique opens up a wide array of design possibilities, from architectural models to complex machinery parts.

What is 3D Printing Bridging?

Bridging in 3D printing involves creating a span between two points without support, akin to building a bridge. It’s a complex task, demanding precision, coordination, and fine-tuning of various parameters such as temperature, speed, and layer height.

The challenge of bridging pushes the boundaries of what 3D printers can achieve and showcases the innovative potential of the technology. It also reflects the evolving sophistication of printers, material science, and software that makes bridging possible.

Why 3D Printing Bridging Tests Matter

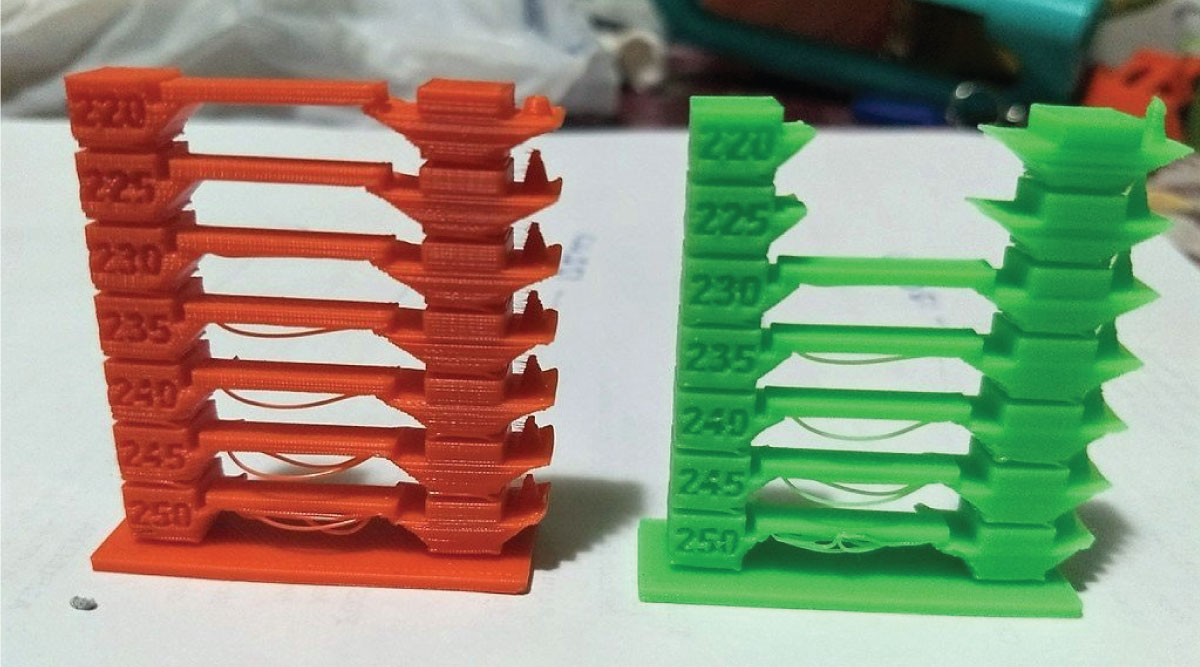

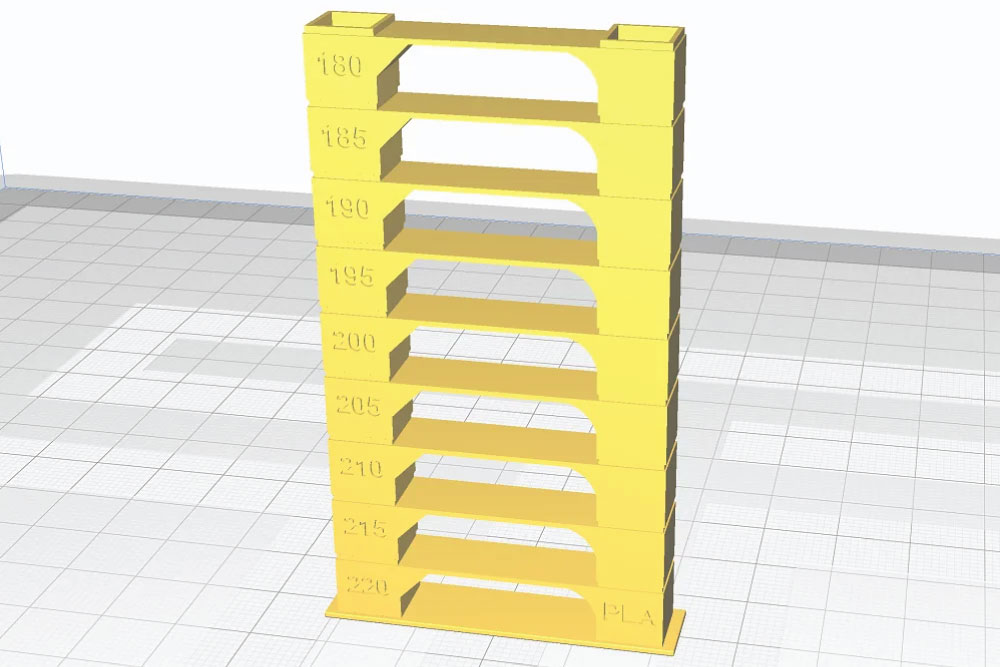

1. 3D Printer Bridge Test

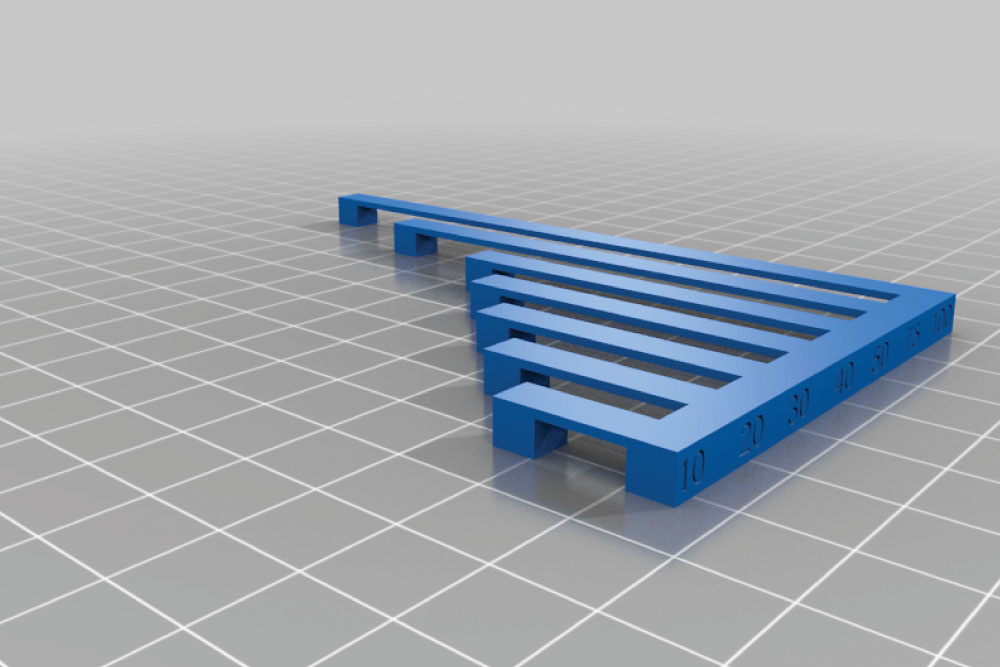

The 3D printer bridge test allows users to gauge the printer’s ability to print flat surfaces without supports. This is an essential aspect, especially in intricate designs, where removing supports can become tedious or even damage the print. By carefully assessing the bridging capabilities, users can prevent structural failures and ensure a more polished final product. The results obtained guide the selection of suitable settings for each specific model.

2. 3D Print Bridge Test

Also known as the bridging test, the 3D print bridge test serves to analyze the printer’s ability to manage overhangs and distances between supports. The results of this test enable users to adjust settings for optimal performance, particularly in designs that include wide gaps or unsupported structures. Implementing the insights from this test can lead to enhanced print quality, reducing the need for post-processing. It also helps to conserve material by eliminating unnecessary support structures.

3. 3D Printer Bridging Test

The 3D printer bridging test is a comprehensive evaluation that goes beyond the simple bridge test. It assesses the 3D printer’s overall capability to handle complex structures and unsupported spans, helping users understand the machine’s limitations and strengths in handling bridging 3D printing tasks. Utilizing this test can lead to a more in-depth understanding of a machine’s particular characteristics, enabling more efficient and creative print designs. It emphasizes the need for continuous learning and adaptation in a rapidly progressing field.

Tips for Achieving Perfect 3D Printing Bridges

The following tips are derived from experienced sources and cover the essential aspects to consider for achieving the perfect “3d print bridge.”

Layer Height and Speed: Adjusting layer height and printing speed is critical. A smaller layer height provides better stability, while slower speeds allow the material more time to cool and solidify. These adjustments can be particularly impactful in reducing the risk of collapse or distortion in longer bridges. They make for an adaptable process tailored to the unique needs of each print.

Temperature Control: Managing the right temperature for both the extruder and the build plate can significantly impact the bridging 3d printing process. An overheated extruder may lead to drooping, while an adequately controlled temperature helps in maintaining the bridge’s shape. Understanding the material’s properties and how they interact with temperature allows for a more nuanced control. It can mean the difference between a failed print and a successful bridge.

Use of Cooling Fans: Cooling fans assist in quickly solidifying the material as it spans the gap. This helps in maintaining the bridge’s integrity, especially in longer spans. Strategically using cooling fans enhances the precision and control over the process. It illustrates the synergy between hardware components and fine-tuned settings in achieving complex prints.

Fine-Tuning Retraction Settings: Retraction settings help in controlling the stringing effect. Fine-tuning these settings reduces the risk of material oozing during the bridge construction. This optimization ensures that the extruder functions at its best, reducing the likelihood of common printing errors. It also allows for cleaner transitions between different sections of the print.

Optimize Print Orientation: The direction in which the bridge is printed affects the final outcome. Analyzing and selecting the optimal orientation minimizes overhangs and ensures a more robust structure. Print orientation can be an overlooked aspect, but its consideration leads to more efficient printing and improved structural integrity. It’s another layer of strategy in the multifaceted world of 3D printing.

Utilizing Specialized Bridging Software: Some software tools are designed specifically to handle bridging challenges. Utilizing these can significantly ease the process and enhance the results. By embracing these specialized tools, users can leverage algorithms and pre-set configurations developed by experts. They bridge the knowledge gap, allowing even newcomers to achieve professional-level results.

Conclusion

Bridging 3D printing is a fascinating and intricate part of the 3D printing world. Through careful calibration and understanding of the 3D printer’s capabilities, perfect bridges can be achieved. By employing the 3D printer bridge test, 3D print bridge test, and 3D printer bridging test, users can continuously refine their techniques to reach a mastery level in this field.

These tests and practices serve as a roadmap for enthusiasts and professionals alike, fostering creativity, innovation, and efficiency. The continuous evolution of bridging technology stands as a testament to the limitless potential and adaptability of 3D printing.