The Future of Manufacturing: The Carbon Fiber 3D Printer

In today’s ever-evolving technological landscape, the carbon fiber 3D printer has rapidly established itself as a powerhouse in the realm of additive manufacturing. The versatility, strength, and reduced weight of carbon fiber components are pushing the boundaries of what is possible in various industries. By combining the capabilities of 3D printing with the incredible strength-to-weight ratio of carbon fiber, innovators are exploring unprecedented possibilities.

Building on this momentum, industries ranging from automotive to aerospace, and even healthcare, are turning to carbon fiber 3D printing as a game-changer. Traditional manufacturing methods often grapple with limitations, be it in terms of design complexity, waste generation, or production time.

The carbon fiber printer, with its ability to layer intricately designed, super-strong components in a fraction of the time, is rewriting these limitations. As sustainability and efficiency become the watchwords of modern-day manufacturing, the fusion of 3D printing and carbon fiber technology offers a promising avenue to achieve both, opening up a new era of innovative design and robust construction.

What is a Carbon Fiber 3D Printer?

A carbon fiber 3D printer is an innovative machine that can produce parts using carbon fiber-infused filaments. This isn’t pure carbon fiber in the way that automotive or aerospace parts might use, but a composite material that blends traditional 3D printing polymers with fine carbon fibers. The outcome is a product that offers the benefits of 3D printing – like intricate design capabilities and rapid prototyping – with the strength and rigidity of carbon fiber.

The advent of carbon fiber printers has opened up a plethora of opportunities in the manufacturing world. Prior to this innovation, the rigidity and resilience of carbon fiber was largely reserved for high-end sectors that could afford the luxury of crafting with this elite material. However, with the melding of carbon fibers into 3D printable filaments, even smaller businesses, educational institutions, and hobbyists can harness its potential. This democratization of access means that a wider array of industries can now experiment with designs that were once untenable due to material constraints. The blend of flexibility in design and the robustness of carbon fiber is heralding a new era in product development and manufacturing.

Why the Hype Around the 3D Printer Carbon Components?

Carbon fiber is renowned for its remarkable properties. It boasts a unique combination of high strength and low weight, making it a sought-after material in aerospace, automotive, and sporting industries. When you integrate the capabilities of a carbon fiber printer with the rapid prototyping and design possibilities of 3D printing, you get components that are not only strong but also uniquely tailored to precise specifications.

Finding the Best 3D Printer for Carbon Fiber

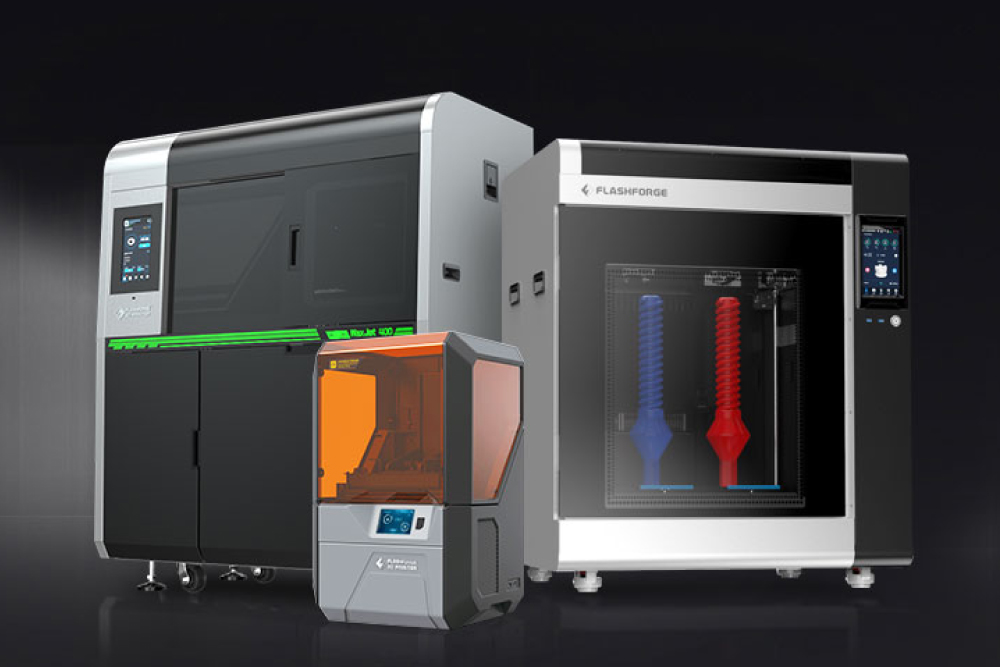

With the soaring popularity of this technology, many manufacturers are delving into the world of 3D printing with carbon composites. So, how does one choose the best carbon fiber 3D printer?

Purpose and Scale: Understanding your needs is paramount. If you’re a hobbyist, a smaller-scale, more affordable option might suffice. However, industries and businesses may require larger, more robust printers that offer high-resolution prints and consistent results.

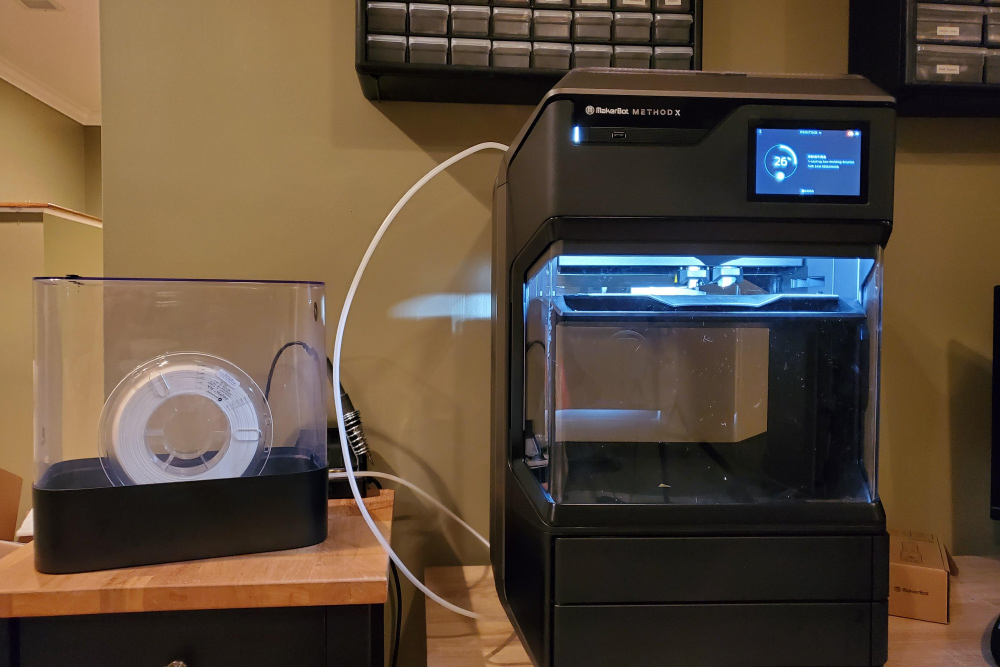

Material Compatibility: While your primary goal might be to print with carbon fiber-infused filament, it’s a bonus if the printer can work with a range of materials, from PLA to PETG, ABS, or even metal-infused filaments.

Print Quality: A printer’s resolution, expressed in microns, is a good indicator. The lower the number, the higher the resolution. But, remember that printing with composite materials like carbon fiber-infused filament might require specific nozzle types to handle the abrasive nature of the material.

Ease of Use: Features like auto-bed leveling, touchscreen controls, and easily swappable filament canisters can greatly enhance the user experience.

Price Point: Carbon fiber printers come in a broad price spectrum. Remember, the most expensive doesn’t always equate to the best. Balance features with budget.

In Search of the Best Carbon Fiber 3D Printer

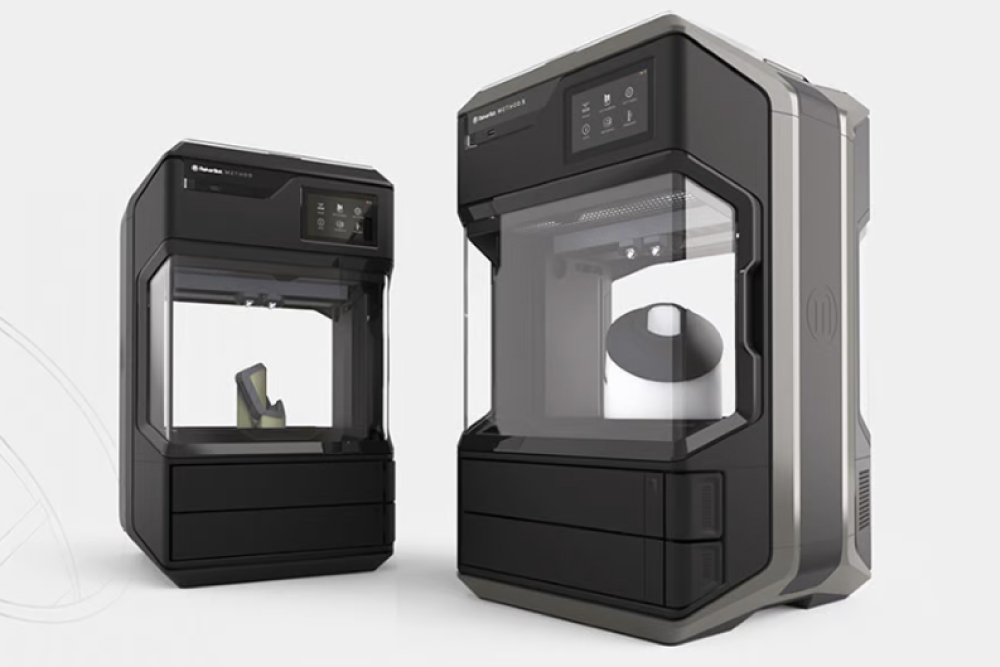

When scouting for the best 3D printer for carbon fiber, you might come across several top-tier options. Basing our search on a trusted source such as All3DP can narrow down the options, offering insights on price points, user reviews, and capabilities. While there might be variations based on specific needs, some of the best options typically blend user-friendly interfaces with high-quality print results and material compatibility.

Conclusion

The marriage of 3D printing technology with the strength and flexibility of carbon fiber is truly a match made in manufacturing heaven. Whether you’re a designer, engineer, hobbyist, or business owner, there’s a carbon fiber 3D printer out there tailored for your needs. With the right choice, you can transform your innovative ideas into tangible, robust, and lightweight components that are set to revolutionize your projects and industries. As with any emerging technology, the key is to stay informed, keep experimenting, and push the boundaries of what’s possible.

In recent years, the demand for carbon fiber 3D printers has seen a significant upsurge, signaling a transformative shift in production methods. This integration not only promises enhanced product longevity but also paves the way for more sustainable and efficient manufacturing processes. The blending of carbon fiber’s resilience with the adaptability of 3D printing is undoubtedly setting the stage for a new era of innovation and design prowess.