Printing PETG : A Comprehensive Guide to Success

Printing petg (Polyethylene Terephthalate Glycol) has become increasingly popular among hobbyists and professionals alike. With characteristics like durability, ease of use, and water resistance, PETG is an excellent choice for various 3D printing applications.

This article provides an extensive guide on PETG printing, highlighting the techniques, benefits, challenges, and addressing the question – is PETG hygroscopic? PETG 3D printing has gained traction due to its unique properties that combine the strength of ABS and the printability of PLA. It’s a versatile material that is becoming a go-to choice for many. Below are the key aspects to consider when printing with PETG.

Understanding the specific properties of PETG, such as its hygroscopic nature, is crucial for successful printing. Proper handling and storage, along with carefully selected printing parameters, can lead to impressive results.

Whether it’s for artistic creations, functional prototypes, or industrial components, PETG’s unique blend of strength and flexibility opens up a world of possibilities. Embracing the techniques and best practices outlined in this guide can transform a novice’s experience into a mastery of PETG 3D printing, unlocking new potential in design and innovation.

What is PETG?

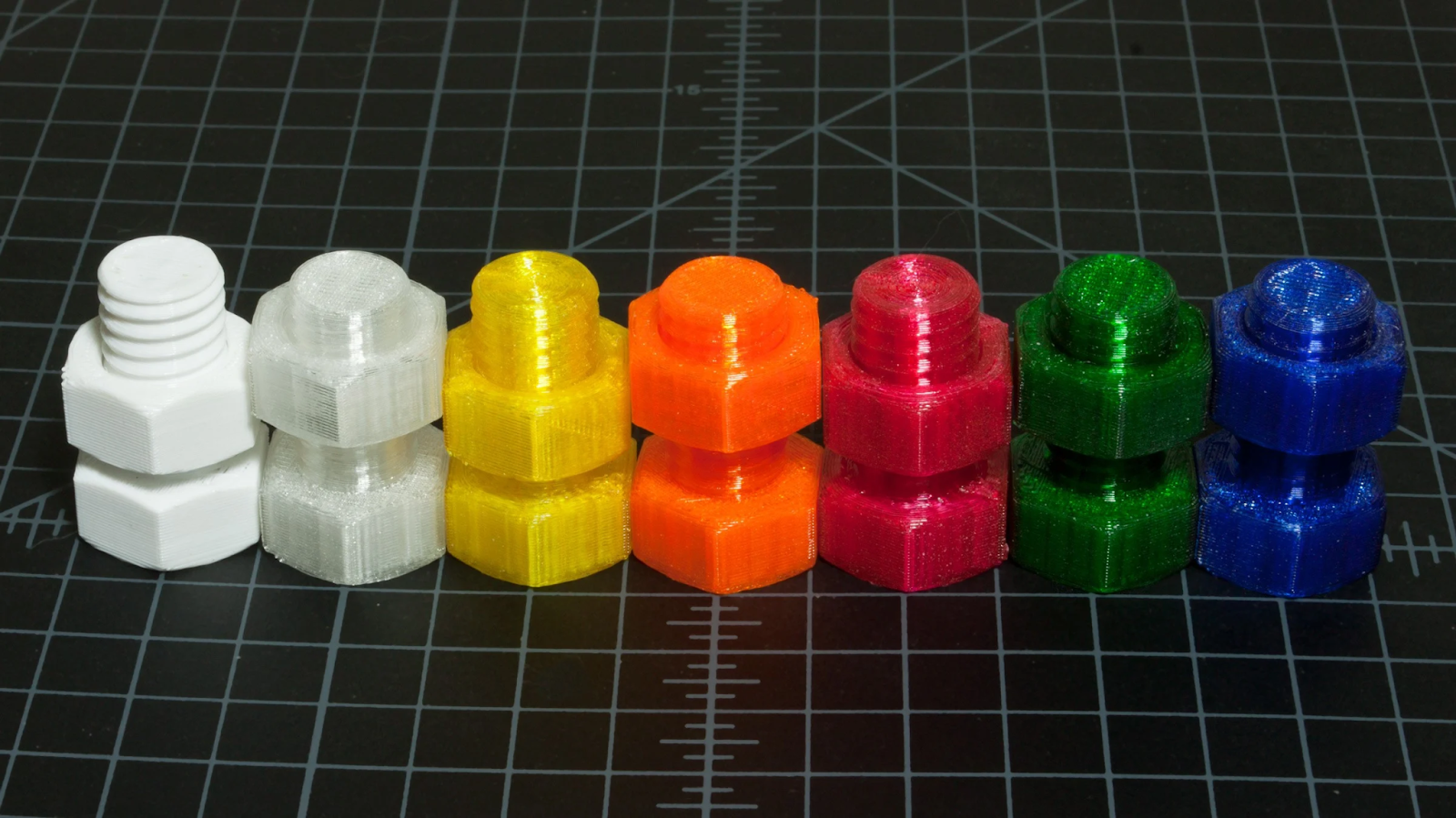

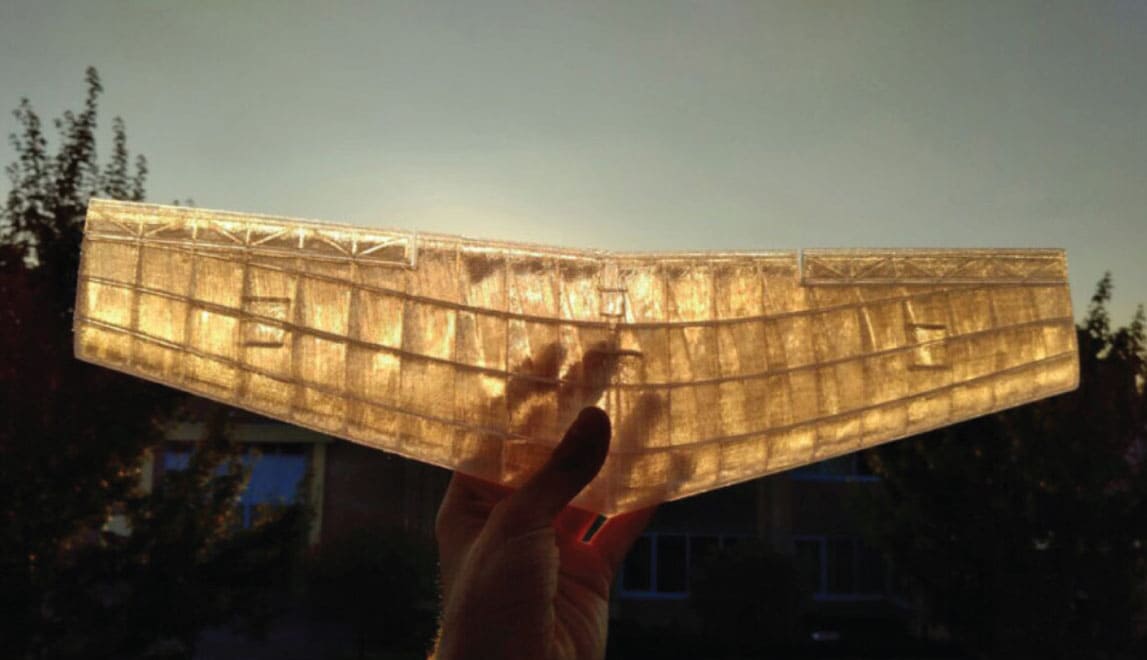

PETG stands for Polyethylene Terephthalate Glycol-modified, a transparent thermoplastic that offers high impact resistance. It’s commonly used in the creation of food containers and mechanical parts. Its popularity in 3D print PETG applications has grown due to its many advantages over other materials. One of the most significant advantages of PETG is its outstanding layer adhesion, which makes the printed parts very strong and resistant to breakage.

Furthermore, its relatively low printing temperature and odorless nature contribute to a more user-friendly experience, broadening its appeal to both beginners and experienced 3D printers. Additionally, PETG’s transparent characteristics offer intriguing possibilities for aesthetic designs, making it a favored choice for applications that require both functionality and visual appeal.

Is PETG Hygroscopic?

Yes, PETG is hygroscopic, meaning it absorbs moisture from the air. This property can make printing with PETG more challenging as moisture can affect print quality. It requires proper storage and handling to minimize exposure to humidity.

Moisture absorbed by PETG can lead to bubbles and inconsistencies in the printed object, often resulting in a weak or flawed final product. Therefore, it’s essential to store PETG filament in a dry environment, such as a sealed container with desiccant, to preserve its quality. Some 3D printing enthusiasts even utilize filament dryers before printing with PETG, ensuring that any absorbed moisture is removed, thereby optimizing the printing process and enhancing the final product’s durability and appearance.

Techniques for Printing PETG

PETG printing needs specific attention and parameters to achieve optimal results. Here’s a guide to some essential techniques:

Bed Temperature and Surface: A heated bed at around 70-80°C is recommended for PETG 3D printing. Surfaces like glass with glue or blue painters’ tape can provide excellent adhesion.

Extrusion Temperature: A hot-end temperature of 230-250°C usually works well when printing with PETG. It’s vital to find the right balance to prevent stringing and oozing.

Cooling: While some cooling is needed, excessive cooling can lead to poor layer adhesion. Experimenting with fan settings is key to finding the optimal condition.

Printing Speed: A slower printing speed (around 30-50 mm/s) helps in achieving better results with PETG.

Retraction Settings: Adjusting retraction settings helps to minimize stringing and can lead to a cleaner print.

Benefits of PETG Printing

PETG offers a blend of qualities that make it suitable for various applications:

Durability: PETG’s toughness makes it ideal for functional parts and prototypes.

Ease of Printing: Though it requires some tuning, once the settings are dialed in, printing with PETG is relatively straightforward.

Odorless Printing: Unlike some other materials, PETG printing doesn’t produce unpleasant odors.

Food Safe: PETG is considered food-safe, expanding its application to containers and kitchen tools.

Water Resistance: Its resistance to water and moisture makes it suitable for outdoor applications.

Challenges and Solutions in Printing PETG

While PETG 3D printing offers many advantages, there are challenges to be addressed:

Moisture Absorption: As PETG is hygroscopic, it needs to be stored in a dry environment, and any absorbed moisture should be removed using a filament dryer.

Stringing and Oozing: These can be minimized by adjusting temperature, retraction settings, and printing speed.

Adhesion Problems: Too much adhesion can cause difficulty in removing the print from the bed. Using a release agent or careful calibration can help.

Applications of PETG

PETG printing is suitable for a wide array of applications:

Medical Devices: Its strength and clarity make it a choice for medical equipment.

Automotive Parts: Durability and resistance to environmental factors make it ideal for automotive components.

Household Items: From vases to utensils, 3D print PETG finds its way into various household products.

Outdoor Equipment: Its water resistance makes it suitable for outdoor gear and fixtures.

Conclusion

Printing PETG has become an essential part of the 3D printing landscape. With its unique combination of strength, flexibility, and ease of printing, PETG is becoming the preferred choice for both enthusiasts and professionals.

Understanding the nature of PETG, including the fact that it is hygroscopic, and adjusting printing techniques accordingly, is vital to success. Whether it’s fine-tuning the temperature settings, adjusting the printing speed, or ensuring proper storage, each step contributes to the final print quality.

With continual advancements in printing technology and a growing understanding of materials like PETG, the future of 3D printing looks bright and versatile. The wide-ranging applications of PETG will continue to drive innovation and creativity in various fields, solidifying its position as a valuable asset in the world of 3D printing.