The Art of the 3D Print Test: What You Need to Know

Mastering the 3D Print Test: Essential Tips

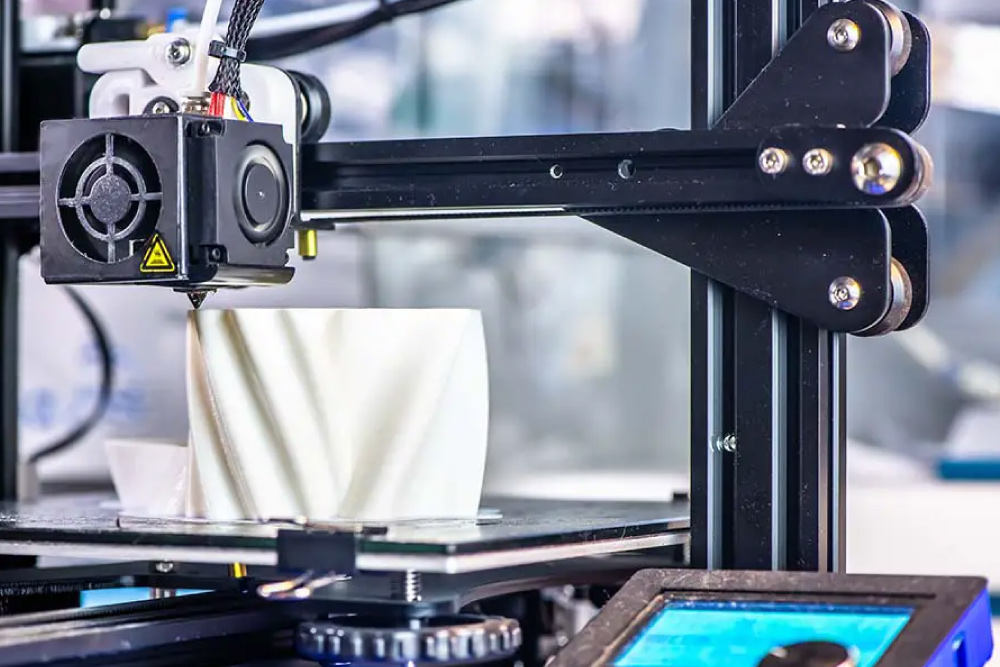

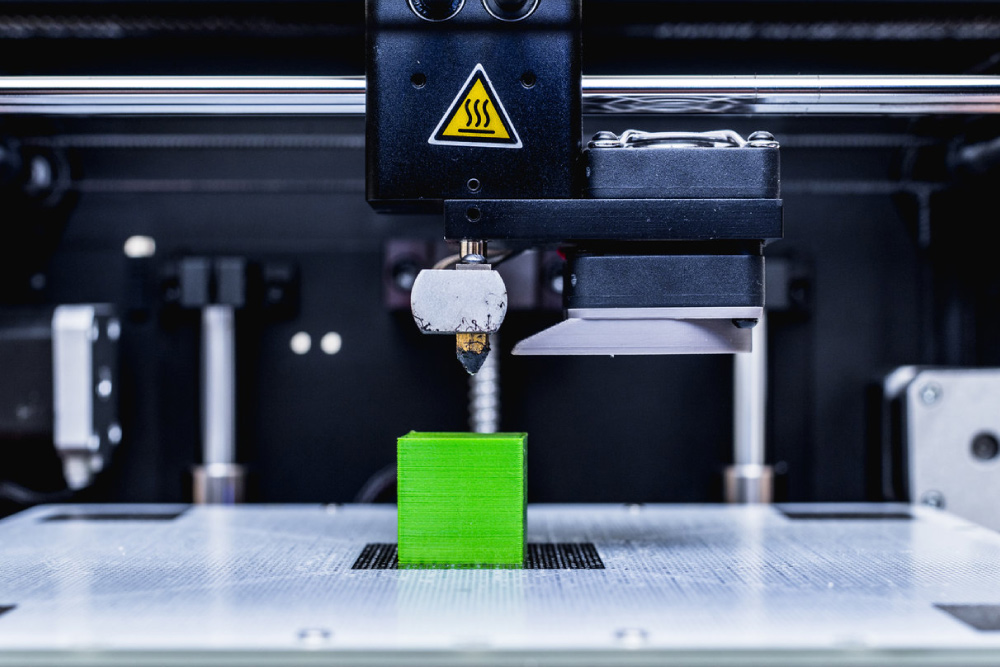

The world of 3D printing has witnessed a dynamic evolution over the years. From creating simple hobbyist projects to complex industrial prototypes, the applications of 3D printing have expanded remarkably. As such, ensuring the precision and performance of a 3D printer becomes paramount. The introduction of the innovative “3D print test” technology marks a significant leap in the realm of manufacturing and quality control. These tests not only safeguard the printer’s longevity but also guarantee the quality of its outputs. By regularly testing and tuning your printer, you ensure that your end products, whether for personal or professional use, meet the expected standards.

With the increasing democratization of 3D printing technology, more individuals and businesses are embracing its potential. This surge in usage underscores the need for consistent printer performance. However, much like a professional chef sharpens their knife before crafting a dish, a 3D printing enthusiast must ensure their equipment is fine-tuned to perfection. The realm of 3D printing is rife with variables, from filament types and ambient conditions to software nuances. As such, a “3d printer test print” becomes more than just a preliminary step—it’s a ritual of preparedness, a commitment to excellence, and a nod to the intricate dance between man and machine, ensuring that every subsequent print captures the essence of the creator’s vision.

Why is a 3D Print Test Essential?

A “3d printer test” is not just a trial run. It’s a diagnostic tool. Much like you wouldn’t drive a new car without ensuring all its systems are working correctly, you shouldn’t start a 3D printing project without ensuring your printer is up to the task. It’s akin to the foundational step of building a house; the foundation must be solid for the structure to stand tall. Ignoring this vital step can lead to wasted resources, be it time, filament, or energy. Recognizing the importance of test prints can be the differentiator between amateurish and professional-quality outputs.

Popular 3D Print Test Models

Various sources, like All3DP, Obico, and Tom’s Hardware, provide a vast list of recommended 3D models that serve as effective printer tests. Here are some universally acknowledged ones:

Benchy: Often termed the “Hello World” of 3D printing, the Benchy boat is a popular choice. This test 3D print not only evaluates the printer’s overhangs, bridging, stringing, and more but its intricate design also pushes the printer to its limits. Benchy serves as a rite of passage for many in the 3D printing community, symbolizing a step into deeper understanding and calibration. Its distinctive shape and features make it easy to pinpoint areas needing improvement.

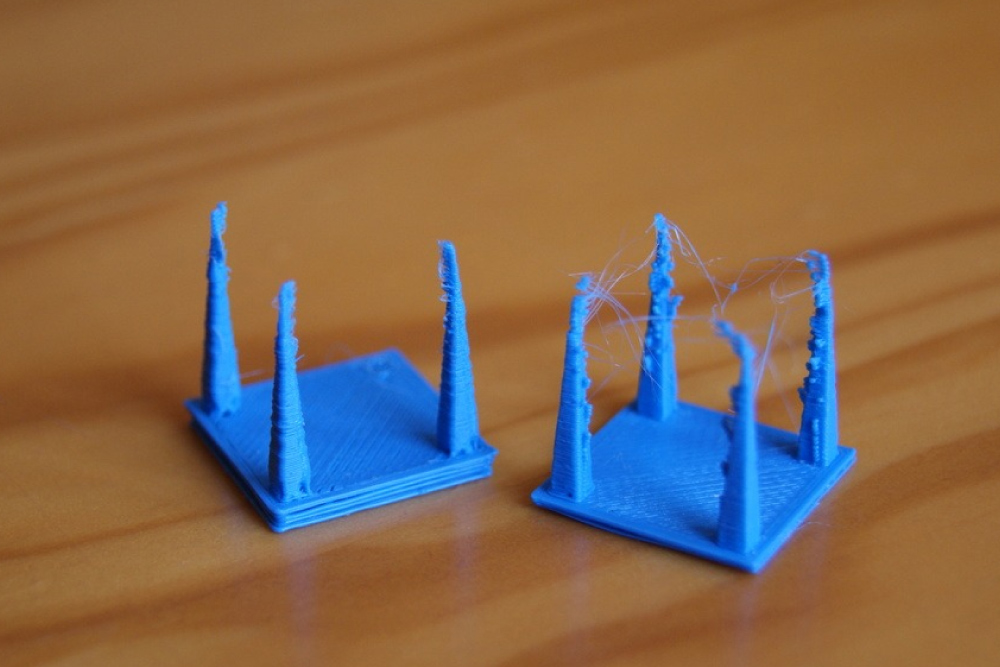

XYZ 20mm Calibration Cube: This cube, with its plain appearance, plays a pivotal role. It helps calibrate the X, Y, and Z dimensions of the printer and ensures its accuracy. But it’s not just about its simplicity. The cube’s design provides clarity on dimensional accuracy, allowing users to make minute adjustments to their printers. It’s an effective tool that ensures each dimension of your prints is on point.

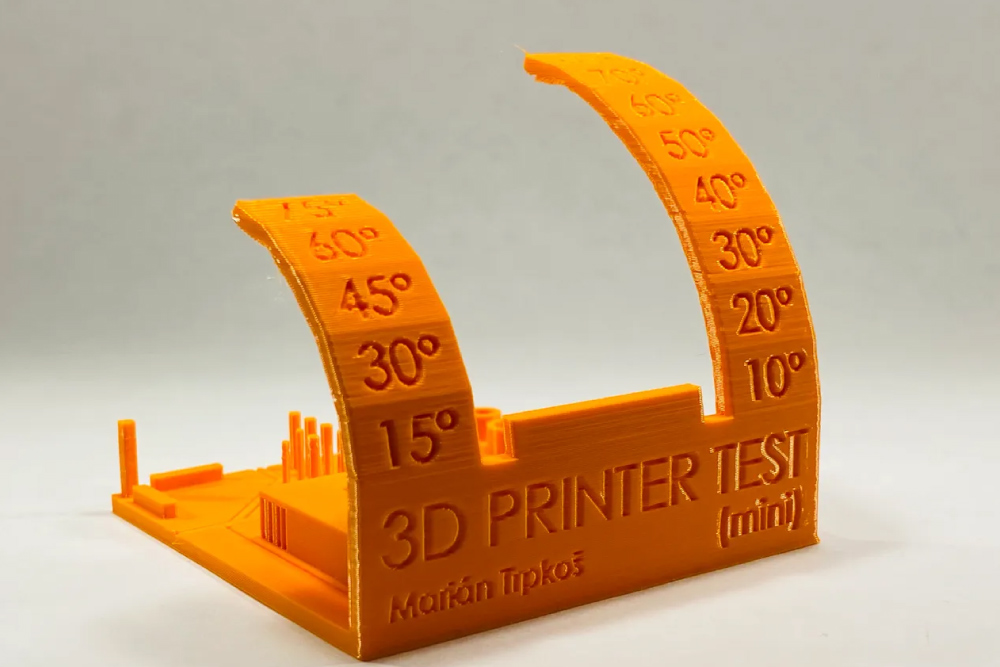

Overhang Test: This test pushes the 3D printer’s capability to print at various angles without support. The better your printer performs in this test, the more complex models it can handle without additional structures. Overhang tests provide an avenue for understanding a printer’s cooling and layer adhesion dynamics. Adequately conducting this test can help reduce print failures in future projects.

Making the Most of Your 3D Printer Test

Now that you have a grasp of why test 3D prints are crucial and some of the popular models to use, here’s how to make the most of your 3D printer test:

Use a Variety: Don’t stick to just one model. Different 3D printer test prints evaluate various aspects of your machine. Rotate between models to get a comprehensive assessment. Each model challenges your printer in unique ways, offering a mosaic of insights into its capabilities. With a diverse range of tests, you’ll be better equipped to handle a myriad of projects.

Document Results: Every time you conduct a 3d test print, make notes. Documenting helps in tracking the printer’s performance over time, enabling better maintenance and calibration. Consistent documentation creates a rich history of your printer’s performance, offering insights into wear and tear patterns. Over time, this record becomes an invaluable tool for predictive maintenance.

Experiment with Settings: Don’t be afraid to play around. Adjust settings like temperature, speed, or layer height to see how they influence the outcome. This not only helps you understand your printer better but also aids in optimizing its performance. Think of it as getting to know a musical instrument; the more you play with its nuances, the better music you produce.

Conclusion

3D printing is an exciting realm, but like any technology, it demands attention to detail and precision. Utilizing 3D printer test prints provides a foundation for this precision, ensuring that every project you undertake achieves the desired result. Whether you’re a novice or a pro, never underestimate the power of a good 3D printer test. It’s more than just a practice run; it’s a roadmap to mastering the multifaceted world of 3D printing, guiding you towards perfection with each print.