High Resolution 3D Printers: Where Precision Meets Excellence

The realm of 3D printing has witnessed significant advancements over the years. As industries strive to achieve greater detail and accuracy in their prototypes and final products, the demand for high-precision products and detailed output has led to the development of high resolution 3D printers that are revolutionizing industries.

Not only have they transformed how we conceive and prototype ideas, but they’ve also shifted the dynamics of production in various sectors. This article delves deep into the world of high resolution 3D printers, understanding their importance, and highlighting the key benefits they offer. With each technological leap, the boundaries of what’s possible are pushed further.

Building on this momentum, high resolution 3D printers stand as a testament to the convergence of art and science. The intricate designs and immaculate precision they offer have opened doors to realms previously thought to be the domain of skilled artisans or complex machinery.

From medical implants tailored to the exact specifications of an individual to architectural models capturing the most nuanced features of a design, the capabilities of these printers have expanded the horizons of innovation. As we tread deeper into this century, it’s evident that the fusion of technology and creativity, made possible by such advancements, will dictate the future trajectory of countless industries.

What is High Resolution 3D Printing?

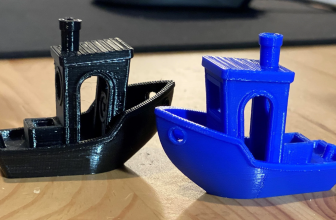

High resolution 3D printers excel by producing highly detailed and refined outputs, setting them apart from other manufacturing methods. These printers offer exceptional precision in crafting objects, with “resolution” in 3D printing referring to the layer height or the thinness of each layer. High resolution 3D printers can achieve layers as thin as 20 microns or even less, resulting in smoother surface finishes. This level of detail allows artists and engineers to bring their most intricate designs to life with unparalleled accuracy.

The Importance of High Resolution

The significance of a high-precision 3D printer cannot be overstated. It’s an amalgamation of science and art, working harmoniously to create precision-crafted outputs. Imagine a world where architects can print detailed building models with tiny windows, doors, and intricate designs. The artistry of jewelry designers or the accuracy demanded by automotive engineers is now within grasp. Or a scenario where the medical field can produce customized implants with precision down to the micron level, ensuring a perfect fit for the patient. This is no longer the stuff of science fiction but a tangible reality today.

Major Advances in High Resolution 3D Printers

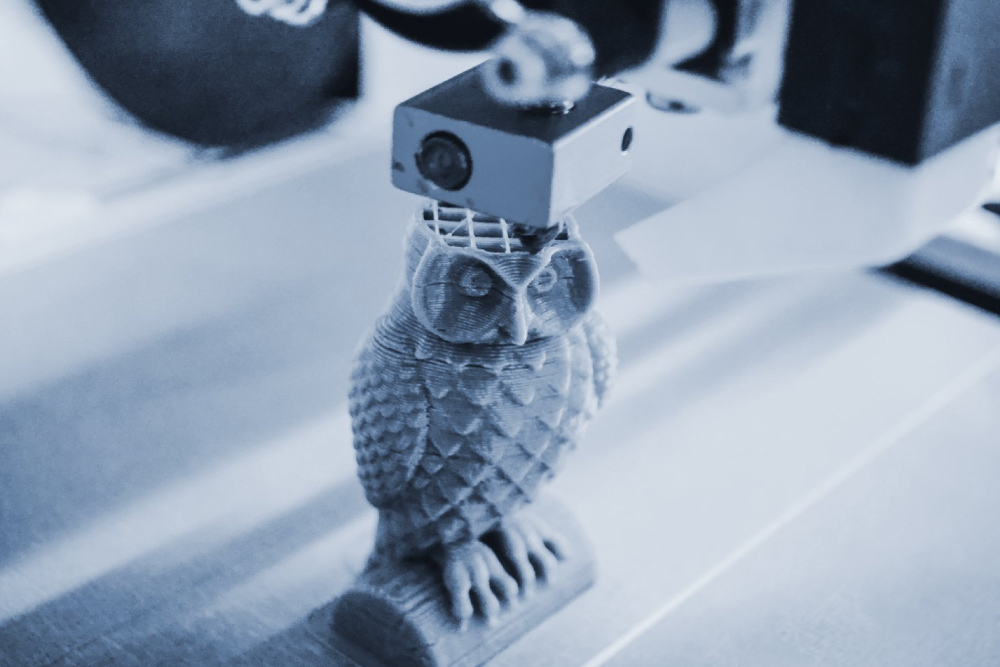

Several technological advancements have driven the surge in high resolution 3D printers. As the tech world delves deeper into miniaturization and precision, these printers follow suit. Stereolithography (SLA) and Digital Light Processing (DLP) are two of the most common technologies used in the highest resolution 3D printer models.

Their unmatched ability to produce micro-layers has revolutionized various industries. Both these technologies utilize a light source to cure photopolymer resin, resulting in layers that are incredibly thin and smooth. The outcome? Objects that are virtually indistinguishable from their digital blueprints.

High Resolution 3D Printers: Competitive Advantages

When delving into the realm of 3D printer high precision, some machines stand head and shoulders above the rest. These aren’t just printers; they’re masterpieces of engineering. These highest precision 3D printer models are typically used in industries where the margin for error is minimal. In fields like aerospace and biomechanics, the minutest of inaccuracies can lead to colossal failures.

For example, in the aerospace sector, components must be precise to ensure the safety and functionality of the aircraft. Similarly, in the medical field, where patient well-being is paramount, accuracy can be the difference between life and death.

Challenges and Factors to Consider in High Resolution 3D Printing

While high resolution 3D printers offer numerous benefits, they also come with challenges. The journey to perfection is not without its bumps. Firstly, they are typically more expensive than their low-resolution counterparts. This high price tag stems from the advanced technology and materials used in their construction. This cost is often justified by the superior quality of prints, but it’s essential to assess the return on investment.

Balancing between cost-efficiency and unparalleled precision is crucial. Another consideration is the printing speed. As they say, perfection takes time. Because high-precision 3D printers focus on detailed output, the printing process can be slower compared to regular 3D printers. But for those who value detail above all else, this trade-off is a small price to pay.

Conclusion

High resolution 3D printers have marked a significant milestone in the 3D printing industry. Their existence is a testament to human ingenuity and the relentless pursuit of perfection. As technology continues to advance, the gap between the digital world and the tangible one narrows, with the help of these printers. By bridging this divide, we are heralding a new era of production and creativity.

They are not just tools but enablers, allowing industries to realize visions that were once restricted to computer screens. Their impact is monumental, reshaping industries and laying the foundation for innovations yet to come. Whether it’s for art, medicine, or aerospace, the future is bright and detailed, thanks to high-precision 3D printers.