The Significance of 3D Printing Raft: An In-Depth Insight

The intriguing realm of 3D printing has revolutionized the manufacturing industry. With its expansive capabilities, 3D printing offers innovative solutions, but like all technology, it presents its own unique set of challenges. One such challenge is ensuring that the first layer of a 3D print adheres properly to the print bed. This is where the concept of a “3D printing raft” comes into play.

Building upon this foundational layer of understanding, the 3D printing raft serves as a testament to the industry’s adaptive nature. As innovators and creators work tirelessly to bring intricate designs to life, they often encounter issues that demand novel solutions. The raft is a reflection of the collective ingenuity of the 3D printing community. Not only does it address the practical concerns of adhesion, but it also represents the ongoing commitment to refining and perfecting the 3D printing process, ensuring that every print, from the most basic to the profoundly complex, stands tall on a solid base.

Understanding the 3D Printing Raft

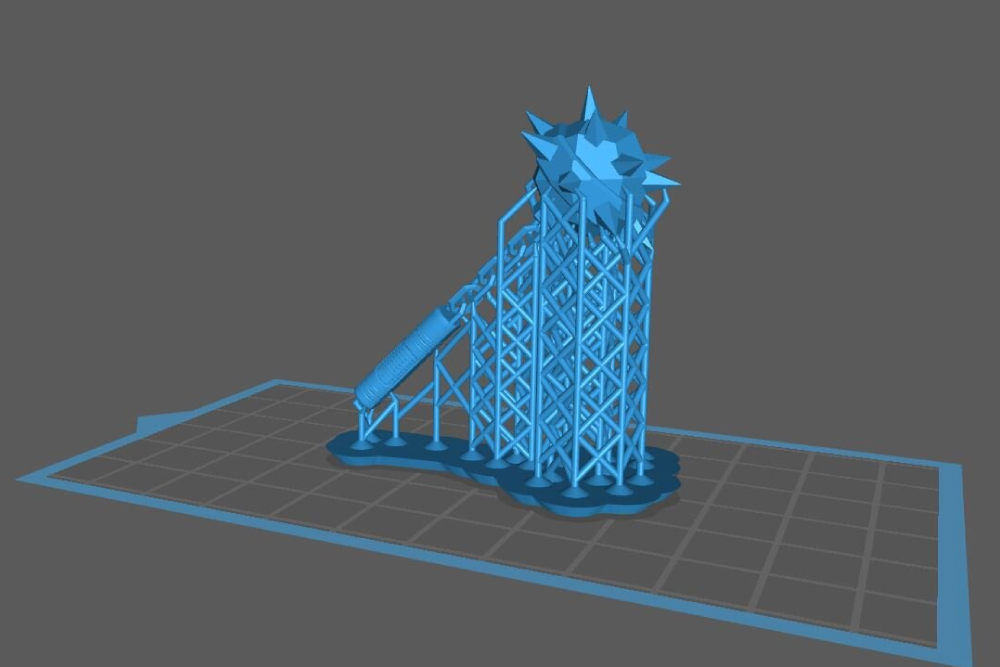

In essence, a 3D print raft is an extra layer that’s printed underneath the primary model. Designed as a series of horizontal lattices, this raft provides a stronger foundation for the main object, ensuring better adhesion to the printing bed. When discussing the nuances of rafts 3D printing, it’s worth noting that the raft itself is not a part of the main object and is typically removed post-printing.

Furthermore, the integration of a 3D print raft into the printing process can significantly enhance the quality of the final product, especially for intricate designs or materials that tend to be problematic. As an intermediary between the print bed and the main model, the raft acts as a buffer, mitigating issues like warping, curling, or poor initial layer quality.

This additional layer also plays a pivotal role in heat distribution, ensuring that the base of the primary object cools uniformly. Consequently, the raft doesn’t just serve a functional purpose but also contributes to the aesthetic appeal of the final print by preventing foundational imperfections.

When is Using a 3D Printer Raft Recommended?

Warped Printing Beds: If your 3D printer’s bed isn’t completely level or exhibits slight warping, a raft can be the saving grace. It accommodates these minor discrepancies, giving your print a better chance to stick throughout the printing process.

Large Objects with Minimal Bed Contact: For objects that have a small surface area touching the bed but span a large height, using a raft can provide additional stability.

Materials Prone to Warping: Some materials, especially ABS, are more susceptible to warping during the cooling process. A 3D printing raft provides added grip, reducing chances of warping.

First-layer Printing Difficulties: If you frequently encounter problems during the initial layers of printing, utilizing a raft can act as a remedy by offering a smoother, more stable base.

Addressing Common 3D Print Raft Problems

Despite the benefits of raft 3d printing, users may sometimes encounter issues. Let’s delve into some typical raft-related problems and their solutions.

Raft Adhering too Strongly: When the 3D printing rafts are difficult to remove, it may be due to a too-narrow gap between the model and the raft. Address this by increasing the air gap in your slicer settings.

Raft Warping: If the raft itself starts warping, consider using a heated bed. This can help maintain consistent temperature and reduce warping tendencies. Moreover, ensure that the first layer of the raft is being printed slowly to allow for better adhesion.

Inconsistent Raft Surface: A bumpy or inconsistent raft surface can be due to filament oozing or improper leveling. Ensure that the print bed is leveled accurately and also check for any clogged extruder nozzles.

Raft Separation Mid-Print: This could be a result of insufficient adhesion. Cleaning the print bed, using adhesive solutions, or adjusting the bed temperature can aid in achieving better adhesion.

Poor Raft-to-Model Adhesion: If the model doesn’t stick well to the raft, consider reducing the gap between them in the slicer settings.

Comparing with Other Techniques

While the 3D printer raft is one method to ensure proper adhesion, it’s not the only option available. Techniques like “brim”, which involves printing a thin layer around the base of the object (but not underneath), also assist in preventing warping. The choice between raft, brim, or other techniques depends largely on the specific challenges faced during printing.

Conclusion

In the multifaceted world of 3D printing, the 3D printing raft emerges as a crucial tool, especially when grappling with adhesion issues. By understanding its purpose, when to use it, and troubleshooting common problems, users can harness the full potential of rafts in 3D printing and achieve impeccable results. Whether you’re a hobbyist or a professional, acknowledging the role of the raft is instrumental in ensuring the success of your 3D prints.