Understanding 3D Printer Infill and its Significance

3D Printer Infill: Explained and Its Significance

In the realm of 3D printing, the term ‘infill’ is a crucial component that often plays a decisive role in determining the physical properties of the printed object. At its essence, 3D printer infill refers to the internal structure of a print. Unlike the solid outer shell that forms the visible part of the print, the infill occupies the interior, offering support and determining the object’s weight and strength. But what exactly is infill 3D printing, and why does it hold such importance?

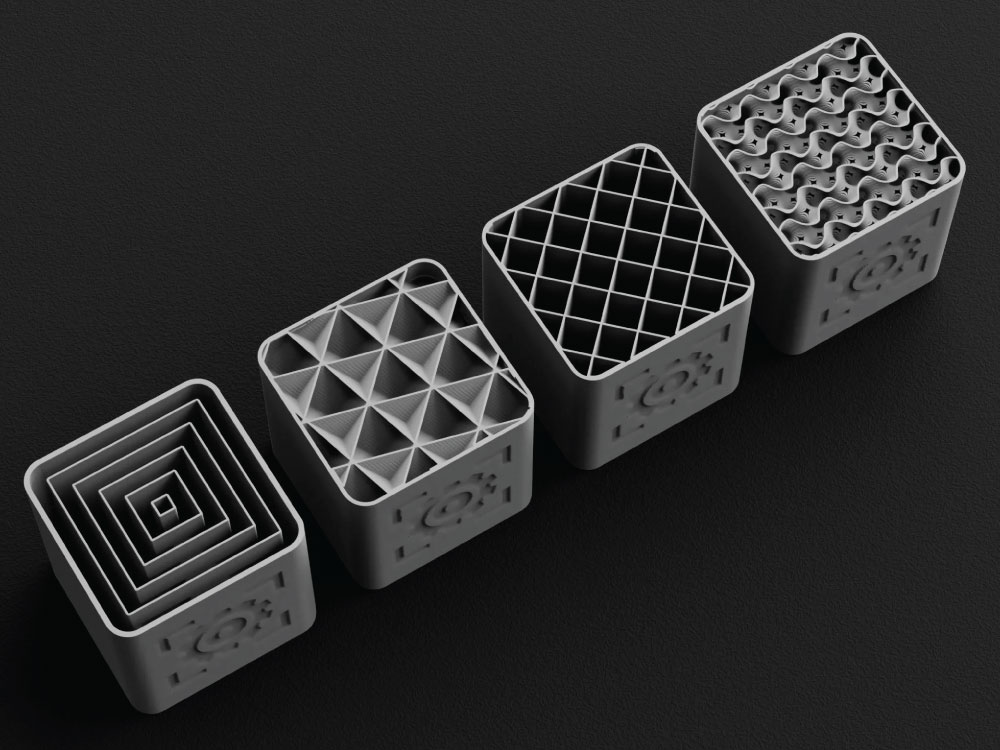

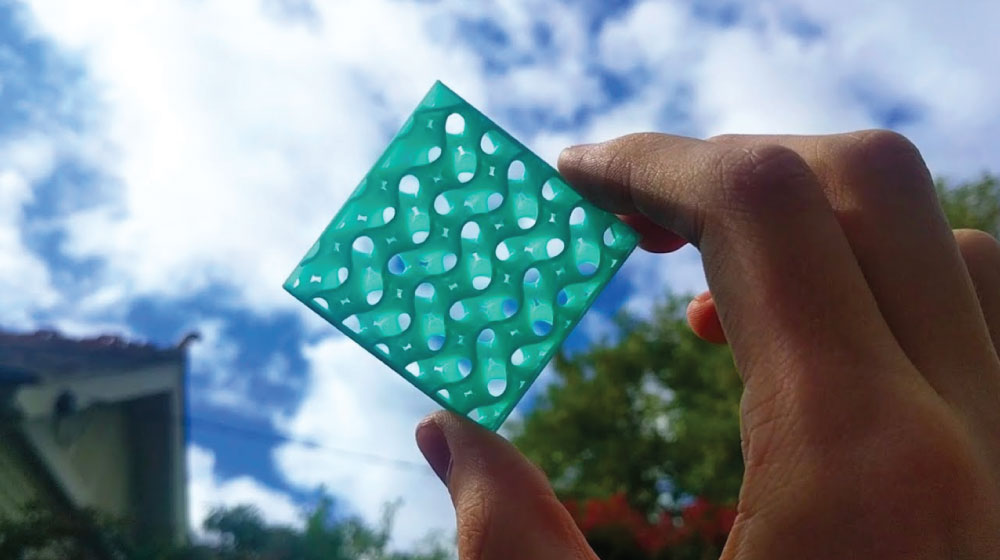

The choice of this lattice structure isn’t arbitrary; it is deeply rooted in the desired outcome of the print. Infill 3D printing ensures that the print is sturdy enough for its intended purpose without wasting materials. Furthermore, the way the infill is designed can play a significant role in the aesthetics of certain translucent or semi-transparent prints. While the external walls give the object its shape, the infill provides it with internal strength and stability. Additionally, the print’s finish and feel can be influenced by the chosen infill pattern. For example, certain patterns might provide more strength in a particular direction.

What is 3D Printer Infill and How Does It Work?

When an object is 3D printed, it’s rare for it to be solid throughout, unless explicitly designed that way. Filling the entire object with material would not only be time-consuming and expensive, but it would also add unnecessary weight. Instead, the interior of most 3D prints is a lattice or patterned structure known as the infill.

Infill 3D printing ensures that the print is sturdy enough for its intended purpose without wasting materials. While the external walls give the object its shape, the infill provides it with internal strength and stability. The design of the infill – whether it’s a grid, triangular, honeycomb, or another pattern – can also influence the print’s properties. For example, certain patterns might provide more strength in a particular direction.

The Importance of Infill Density in 3D Printing

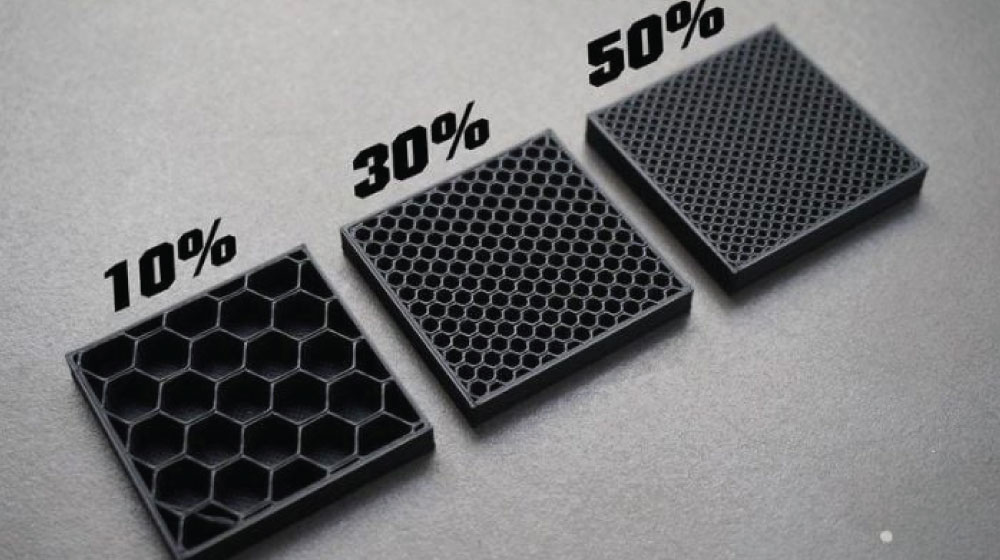

Infill density 3D printing is a term that refers to how tightly packed the infill pattern is within the print. Density is usually expressed as a percentage. A 10% infill means that 10% of the interior volume is occupied by the infill material, with the remaining 90% being empty space. On the other hand, a 100% infill would mean the object is entirely solid.

The density chosen can have several implications:

Strength and Weight: A higher infill density typically results in a heavier and stronger print. For items that need to bear weight or endure stress, like tools or functional parts, a denser infill might be required.

Material Use and Print Time: More infill means more material consumption and longer print times. Thus, for decorative items or prototypes where strength isn’t a primary concern, a lower infill might be preferable.

Flexibility: Prints with lower infill can be more flexible, which might be desired in certain applications.

Tips for Optimizing Your 3D Printer Infill

Selecting the appropriate infill for a 3D print project isn’t just about choosing a pattern or density. It’s about understanding the end purpose of the printed object. Do you need it to be as robust as possible? Or is saving time and material more critical?

For beginners, it might be tempting to opt for a solid, 100% infill for every print, thinking it guarantees the best result. However, in many cases, a 20% or 30% infill is more than adequate. Most 3D printing software offers previews, allowing users to visualize the internal structure before printing. This can be an invaluable tool in optimizing the infill settings.

The art of 3D printing is deeply intertwined with the science of material conservation and structural optimization. Infill, as a foundational concept in 3D printing, embodies this synergy. As designers and engineers continue to push the limits of what printed objects can achieve, the role of infill becomes ever more critical.

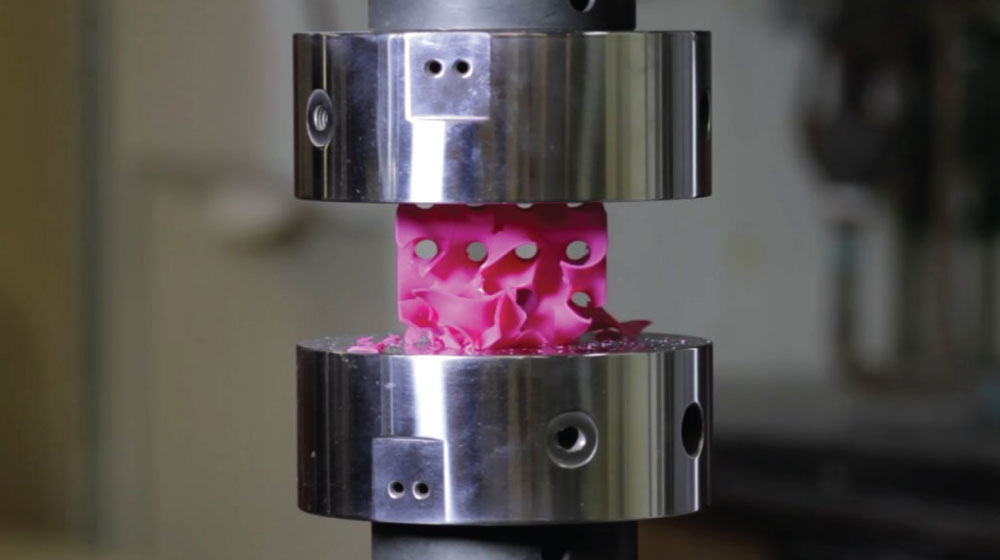

The right infill pattern can ensure a structure is not just strong, but also lightweight and efficient in terms of material use. It can influence the tactile feel of an object, its thermal properties, and even its acoustic characteristics. With the advent of AI-driven design tools and more adaptive printing software, the potential variations in infill patterns are set to explode. This ushers in a future where prints are not only optimized for their primary function but also for environmental sustainability and resource efficiency.

Conclusion

3D printer infill is more than just a filler. It’s a strategic component that influences the final print’s weight, strength, flexibility, and even cost. Whether you’re new to 3D printing or an experienced enthusiast, understanding the nuances of infill can make the difference between an average print and an exceptional one. As with all things in 3D printing, experimentation is key. Adjusting infill settings and observing the outcomes can offer deeper insights into how infill impacts your specific prints. And as the technology evolves, we can only expect even more sophisticated infill options in the future, further pushing the boundaries of what’s possible in 3D printing.