The Top 3D Printer Jewelry to Choose

The Top 3D Printer Jewelry to Choose

The Digital Transformation of Jewelry Design

Traditional jewelry-making is known for its meticulous craftsmanship, but it is a time-consuming and labor-intensive process. Jewelers and goldsmiths are recognizing the need for faster and more cost-effective production methods. In response to this demand, 3D printing, or additive manufacturing, has emerged as a transformative solution.

The 3d printer jewelry market is currently experiencing rapid growth, projected to reach a value of over $22 billion by 2030 . This digital revolution is reshaping the jewelry industry, enabling a shift towards more efficient and innovative production methods. With 3D printing, jewelry-making has taken a leap into the digital age, unlocking new possibilities for creativity and efficiency.

The Advantages of Jewelry 3D Printing:

- 3D printer jewelry primarily involves creating wax (or other material) patterns or models.

- Directly 3D printing jewelry in precious metals is less common due to accessibility and cost constraints for independent jewelers.

- For direct precious metal printing, binder jetting and powder bed fusion technologies are used by companies like Desktop Metal, HP, and Digital Metal.

- In the most common approach, 3D printer jewelry replaces the traditional carving of hard modeling wax.

- Jewelers use computer-aided design (CAD) software to create or modify designs and then 3D print them as wax patterns.

- The traditional lost wax casting process follows, where the wax model is encased in a hardening plaster-like medium and then heated to melt away the wax, leaving a mold filled with molten precious metal.

- A 3D printer for jewerly allows for finely detailed master wax models and quick customization through digital files, speeding up design development and enabling mass customization.

Advantages of 3D printing wax models:

1. Speed: 3D printing is significantly faster than hand-carving wax, producing detailed models in hours instead of days.

2. Complexity: 3D printers can create intricate geometries that may be challenging or impossible to achieve through hand-carving.

3. Customization: Digital CAD files allow quick modifications to meet specific customer requirements, offering personalized jewelry options.

4. Mass Production: With a suitable 3D printer, multiple wax models can be printed in one run, streamlining production for larger quantities.

5. Reproduction: Digital CAD files enable easy reproduction of old or lost jewelry pieces, preserving designs for future use.

6. Cost-Efficiency: Jewelry-scale 3D printing minimizes material usage, reducing material costs and wastage.

7. Quick Prototypes: Clients can try on 3D printed models to ensure a perfect fit and visualize the final piece more accurately than with 2D images.

What to Look For?

When choosing a jewelry 3D printer, the technology is a crucial factor to consider. Resin-based methods like SLA, MSLA, and DLP are popular among jewelers for their high printing resolution and the availability of wax resins suitable for clean burnout during casting.

Material jetting is another resin technology that offers faster printing, especially for large-volume production, with extremely fine detail resolution.

While some filament-based FDM printers can use wax filaments, they may not achieve the level of detail required for intricate jewelry designs. Resin printers are generally the preferred choice, though FDM printers are known for their faster printing speed.

Other considerations when picking your 3D jewerly printer.

1. Resolution: Opt for a printer with the finest detail capability, ideally down to 8 microns or even in the 2 to 5 microns range for micro 3D printing.

2. Print Speed: Look for a machine that offers adjustable speed settings to balance fast but less detailed prototypes with slower printing for intricate designs.

3. Material Compatibility: Choose a printer that supports various materials, including third-party options, to access the best-suited wax resin for your needs and avoid limitations.

4. Cost: Besides the initial printer price, consider maintenance and material costs, ensuring the investment fits within your budget.

5. Exposure: Be cautious with LCD technology if your designs require fine features and smooth surfaces, as some LCD machines may produce pixelated surfaces.

6. Volume: Select a machine suitable for your production needs; smaller volume printers work for limited quantities, while larger volume machines are better for mass customization.

7. Accessories: Take into account additional equipment required, such as washing and curing machines, to ensure a complete and efficient printing process. Look for companies that offer comprehensive packages.

For budget-conscious jewelers new to 3D printing, there are affordable options available. Machines like the Elegoo Mars 2, priced at around $200, offer a good entry point to the technology. However, keep in mind that it may not provide the super fine resolution desired by some jewelry makers.

Our Top Picks & Listing Criteria

For budget-conscious jewelers new to 3D printing, there are affordable options available. Machines like the Elegoo Mars 2, priced at around $200, offer a good entry point to the technology. However, keep in mind that it may not provide the super fine resolution desired by some jewelry makers.

In the mid-range category, there are 3D printers available for professional jewelers that offer advanced features, software, and automation. These printers typically come with a reasonable price tag, under $20,000. When considering printers in this range, look for companies that provide an integrated workflow, where the software, printer, and accessories like washing and curing stations work seamlessly together to enhance efficiency.

Below are few of list of the best 3d printer for jewelry;

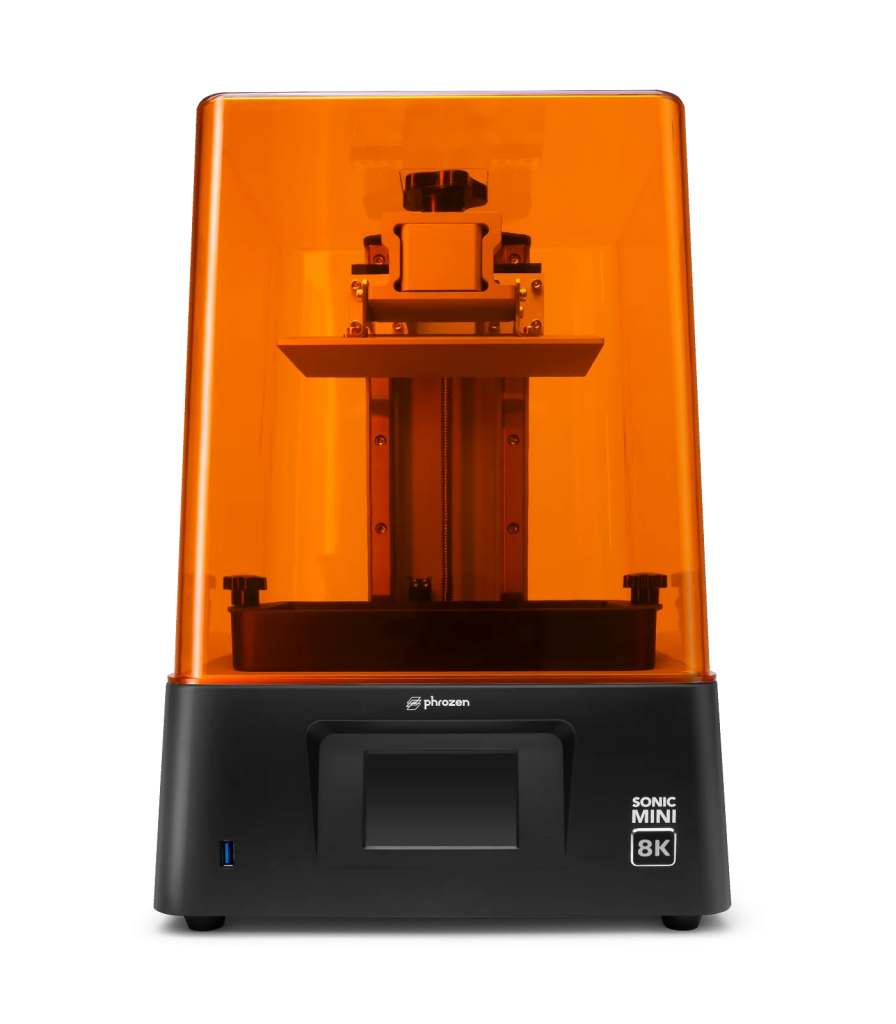

1. Phrozen Sonic Mini 8K:

High-resolution SLA printer with excellent detail and ease of use. Price: $700.

2. Elegoo Saturn 2:

MSLA printer with a large build volume and air purifier. Price: $550.

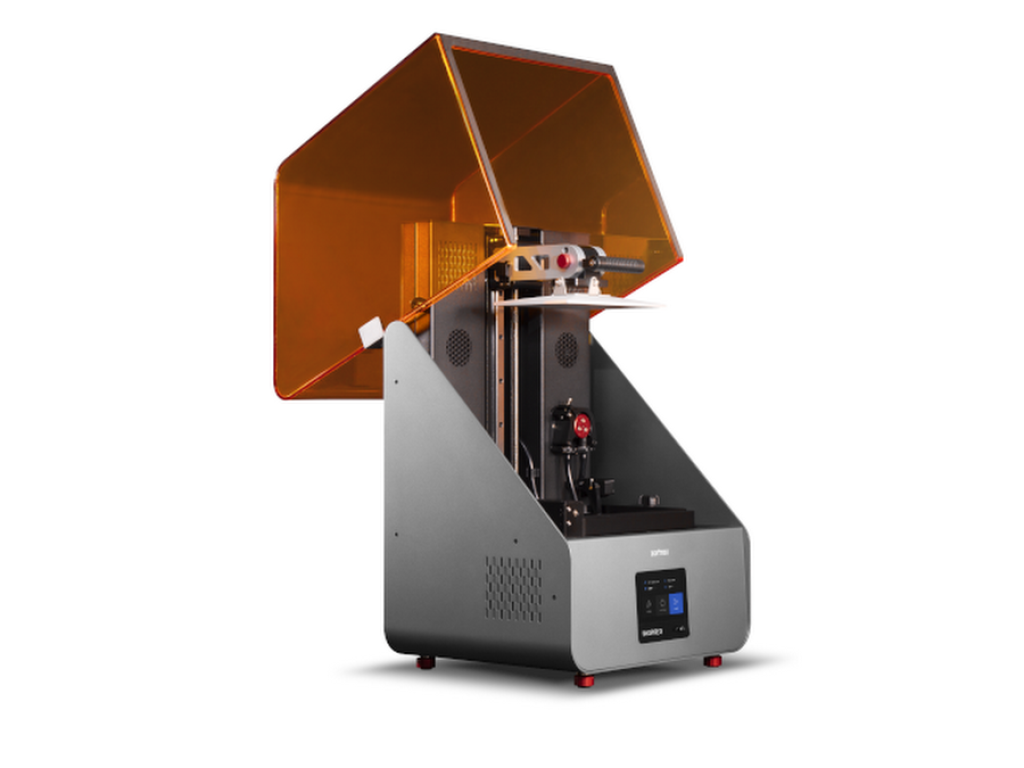

3. Zortrax Inkspire 2:

UV LCD printer with automatic calibration and cloud-based control. Price: $4,500.

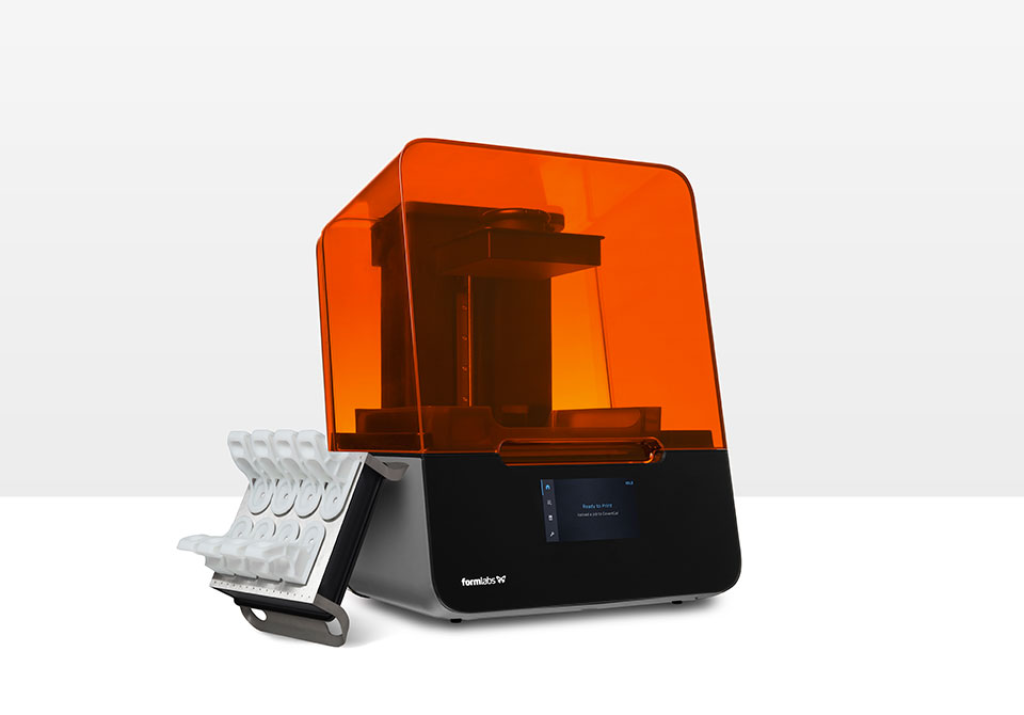

4. Formlabs Form 3+:

SLA printer with faster printing speeds and resin clarity. Price: $3,750.

5. DWS XFab 2500HD:

SLA printer with Nauta XCluster software for jewelry applications. Price: $13,000.

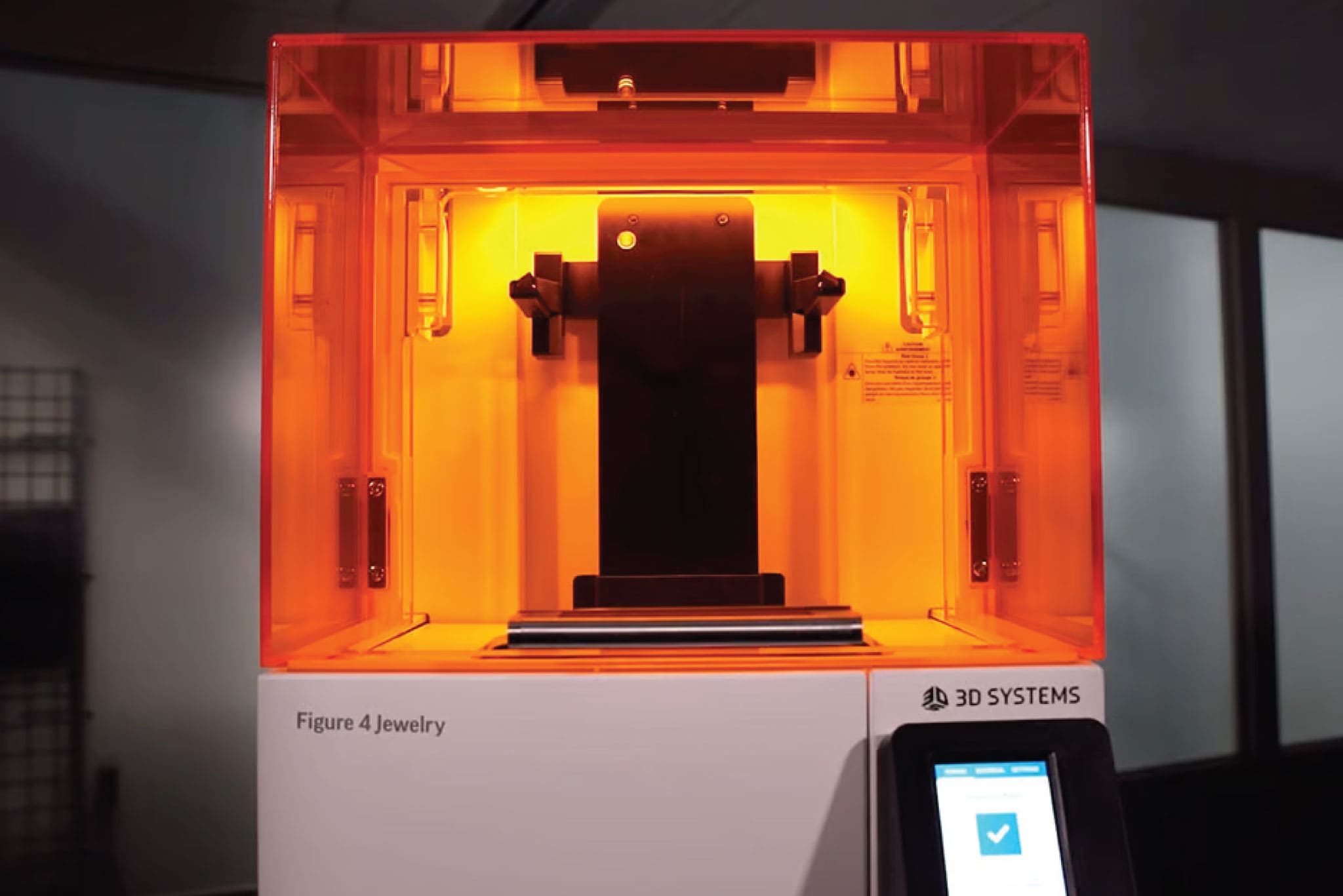

6. 3DSystems Figure 4 Jewelry:

DLP printer for casting and master models. Price: $12,000.

7. ETEC D4K:

High-resolution DLP printer with an open material system. Price: $16,000.

8. Solidscape S325:

Material jetting printer for wax models with precise surface finish. Price: $21,000.

9. AsigaPro 4K80:

DLP printer with 4K imaging and wide material compatibility. Price: $26,000.

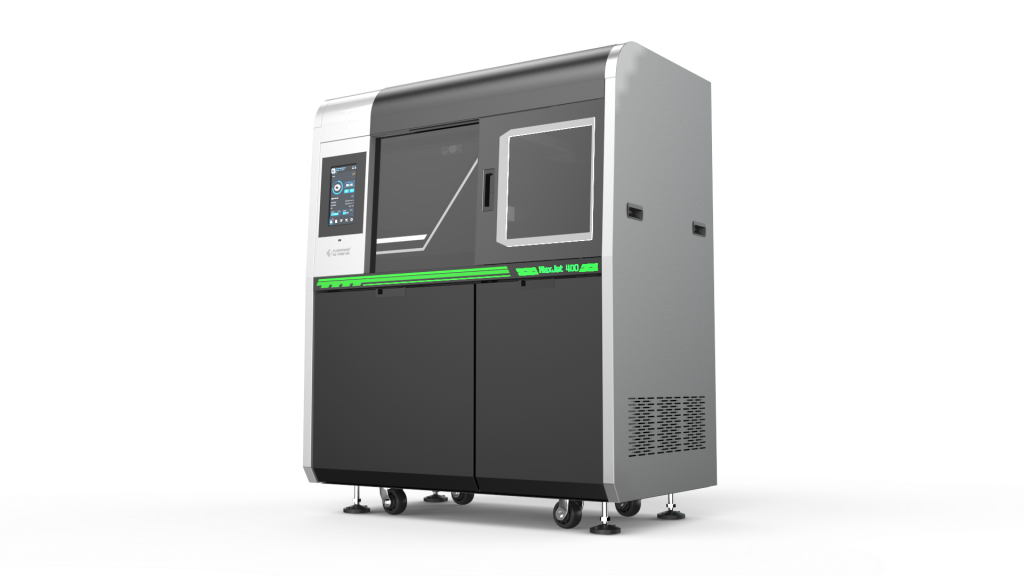

10. Flashforge WaxJet 400:

Material jetting printer optimized for fast mass production. Price: $52,000.

11. RapidShape S30+ L:

Intuitive DLP printer with high-volume printing capabilities. Price: Not Available.

12. 3D Systems ProJet MJP 2500W Plus:

High-speed MJP printer for detailed wax patterns. Price: $70,000 – $85,000.

Get Your Jewelry Printed

If you’re not ready to buy your own 3D printer for jewelry making and need third-party printing services, consider using platforms like Craftcloud. These services allow you to upload your 3D file and choose materials, offering the convenience of receiving the printed model by mail. Some providers even offer metal casting, polishing, and finishing for final jewelry pieces in precious metals like gold, silver, and platinum. Craftcloud, a marketplace for 3D printing services, can help you find the right service for your jewelry making needs.