Unveiling the Magic of the 3D Chocolate Printer

The sweet world of chocolate and the tech-driven realm of 3D printing have converged, bringing forth a scrumptious revolution in the form of the 3D chocolate printer. Imagine customizing your favorite treat not just in flavor but also in the very form and design you desire.

The idea that chocolate can be turned into complex, intricate designs using a printer is nothing short of remarkable. But how does a chocolate 3D printer work, and what possibilities does it unlock? Let’s take a closer look.

The intersection of tradition and technology often leads to groundbreaking innovations, and the 3D chocolate printer stands as a testament to this. With its inception, the culinary and tech worlds have found an enchanting point of collaboration. Gone are the days where confectionery creations were bound by the constraints of hand molds and manual techniques.

Now, precision, artistry, and imagination come alive with every print, redefining our relationship with this beloved treat. As we stand on the precipice of this new age of dessert design, it’s essential to understand the transformative impact this printer brings to both industry professionals and chocolate aficionados alike.

The Magic Behind the 3D Chocolate Printer

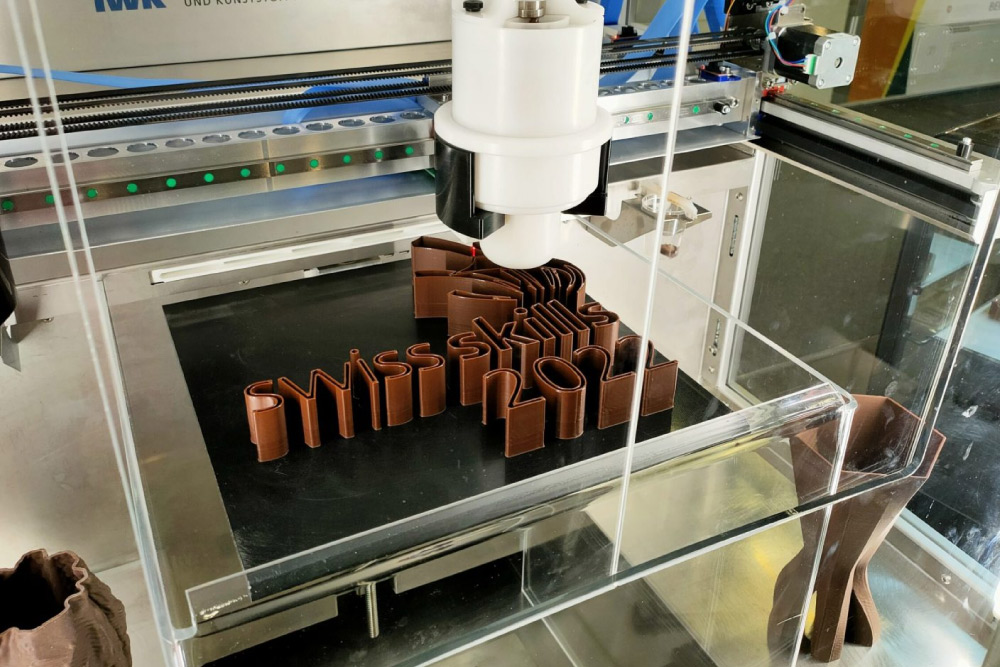

At its core, a 3D chocolate printer works similarly to a typical 3D printer, only it uses chocolate instead of plastic or metal filaments. The magic begins with melting chocolate, which replaces the traditional printer filament. Once the chocolate is in a semi-liquid state, the printer’s nozzle moves in three dimensions to deposit the chocolate layer by layer, forming the desired shape. As the 3D printed chocolate is layered, it cools and solidifies, preserving its new, unique form.

The process of 3D printing chocolate isn’t as simple as just melting and shaping, though. The chocolate must be tempered perfectly to ensure a glossy finish and crisp snap, hallmarks of quality chocolate treats. This tempering process ensures that the fat crystals in the chocolate are uniform, which in turn results in a product that looks and tastes exquisite.

The World of Customized Treats

One of the biggest draws of the chocolate printer is the customization it offers. Traditional chocolate molds can be limiting, but with 3D printed chocolate, the only limit is one’s imagination. Whether it’s a personalized message for a loved one, a company logo for a corporate event, or a bespoke design for a special occasion, the 3D chocolate printer can make it happen.

It’s not just about the aesthetics, either. These printers can be used to create unique textures in the chocolate, leading to new and delightful mouthfeels that aren’t possible with conventional methods. From intricate lattices to hollow spheres, the 3D printing chocolate process redefines the sensory experience of enjoying chocolate.

The Future of Chocolate Printers

While the technology is awe-inspiring, it is still in its nascent stages. Current chocolate 3D printers are primarily found in high-end pastry shops or specialized businesses. They remain a luxury due to their price and the skill required to operate them effectively. However, as with most technology, it’s anticipated that the cost will decrease and accessibility will increase as it becomes more mainstream.

One intriguing possibility for the future is the incorporation of multiple flavors in one print. Imagine a multi-layered treat where each layer is a different type of chocolate or contains various fillings. With the advancement of chocolate printers, such delectable innovations might not be too far off.

Furthermore, as the technology becomes more accessible, it’s likely that we’ll see a surge in personal use. Chocolate enthusiasts might have their own 3D chocolate printer at home, allowing them to experiment and create their own masterpieces. This technology might even pave the way for a new breed of chocolatiers, passionate individuals who merge artistry with the digital age.

Conclusion

The convergence of the culinary arts with technological advancements in the form of the chocolate 3D printer promises a future of unlimited potential in the world of confections. It’s an exciting prospect for chocolate lovers everywhere, blending the age-old joy of chocolate with the futuristic wonder of 3D printing.

The evolution of technology has often given rise to new forms of art and expression. From the invention of the camera to the digital revolution, every significant technological advancement has expanded our horizons. Now, with the advent of the 3D chocolate printer, we are witnessing another transformative moment.

This isn’t merely about creating an edible product; it’s about redefining the very essence of confectionery craftsmanship. Melding the rich traditions of chocolate-making with the precision and versatility of 3D printing, artisans and enthusiasts alike are set to explore uncharted territories of taste and design. The stage is set for a chocolate renaissance, where every bite tells a story of both heritage and innovation.

As the world of 3D print chocolate continues to grow and evolve, it’s clear that the boundary between what is possible and impossible in chocolate design is being continually redrawn. What once was the realm of imagination is now a tangible, edible reality, thanks to the magic of the chocolate printer.